Originally published on fastradius.com on April 27, 2020

Plastic parts are a ubiquitous part of daily life. From food packaging and gardening tools to laptops and sports equipment, it’s hard to go a day without interacting with manufactured plastic parts.

One of the reasons that plastics are so prevalent is that they’re a malleable and adaptable family of materials that can be used to create a wide variety of part types, from soft and flexible components that can withstand repetitive movements to harder, impact-resistant pieces that remain durable even in extreme temperatures.

There are several different methods that manufacturers can use to create plastic parts, including injection molding, 3D printing, urethane casting, and CNC machining. CNC machining is among the most common, due to its reliability, compatibility with a wide range of materials, and ability to create parts with complex geometries. However, there are certain considerations to keep in mind during the design and production lifecycles. This article will explain what you should know before making plastic parts with CNC.

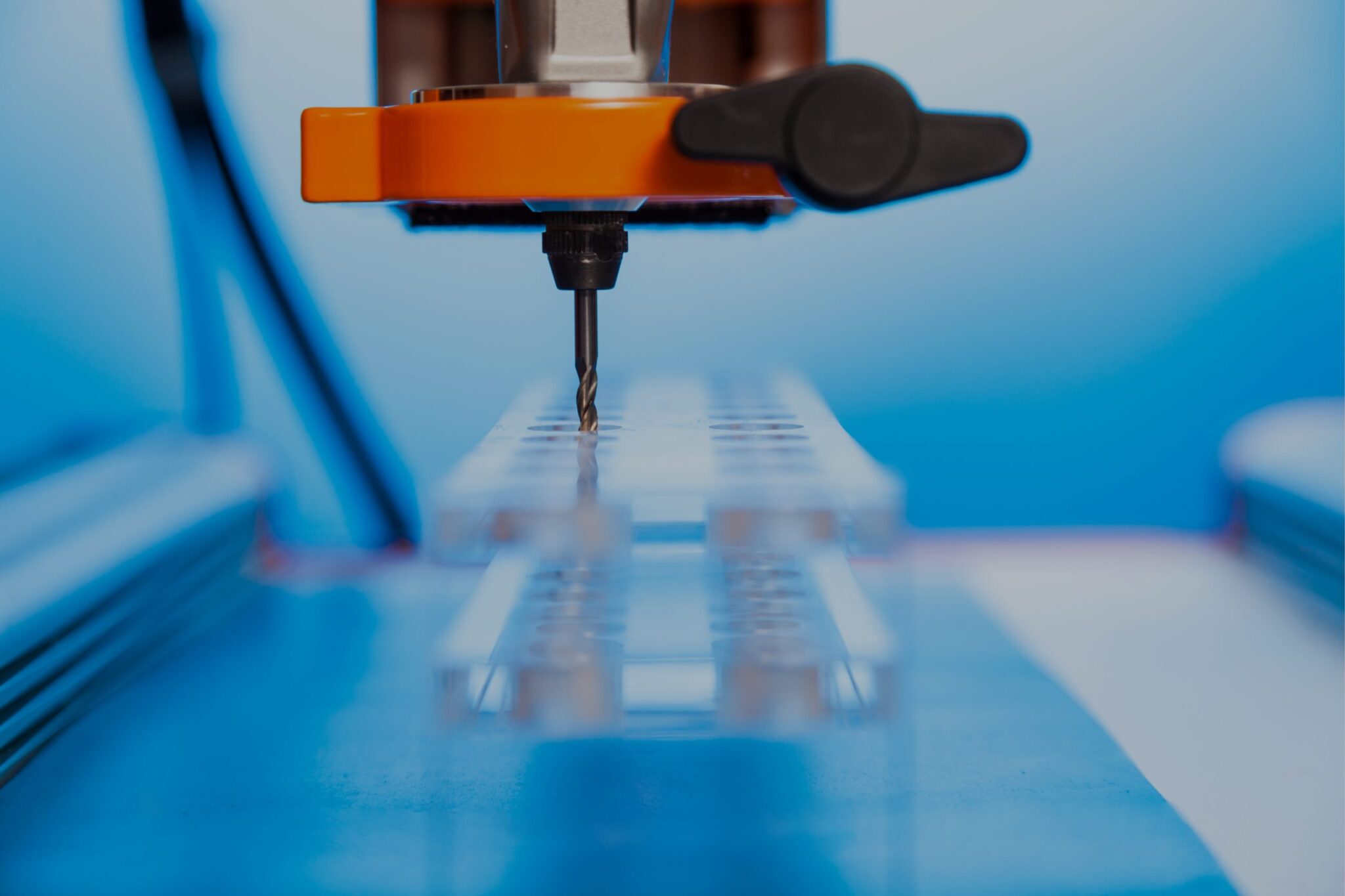

CNC machining is a subtractive manufacturing process that uses rotating computer-controlled cutting tools like drills, end mills, and turning tools to remove material from a solid block of material, thereby shaping the part.

Digital design files direct the CNC machines how to cut the block (also known as the “workpiece”) and multiple machines can use the same design file at the same time, which greatly increases the speed of the production process.

Among the principal considerations for machining plastic parts is the shape of the desired piece, which will help determine whether a 3-axis or a multi-axis machining process makes the most sense. The 3-axis CNC machining processes involve moving the cutting tool along the X, Y, or Z axes while either the tool or the workpiece rotates.

Multi-axis processes, on the other hand, allow both the tool and the workpiece to move simultaneously, enabling manufacturers to produce parts with complicated geometries faster, more accurately, and without the need to reposition or rotate workpieces between operations.

The axial restrictions of CNC machining means that part designs must guarantee adequate tool access. This can make certain designs, such as curved internal channels, extremely difficult or impossible to make — which may lead to extensive design for manufacturability (DFM) revisions in order to make production cost-effective.

Additional features that increase part complexity, such undercuts or design elements on multiple part faces, can potentially require the workpiece to be rotated one or more times, contributing to higher production costs and longer lead times.

However, because machining is a subtractive process, problems like inadequate wall thickness, draft angles, and sink marks (which would typically be addressed in the design phase for casted or molded plastic parts) are less of a concern, which makes CNC machining a good choice for part designs that are difficult to mold. The precision of machining processes also allows manufacturers to create plastic parts with extremely tight tolerances.

Another key consideration is the size of the production run. Some manufacturing methods demand significant upfront investments (such as for tooling the molds required for injection molding), but the low to moderate setup costs required by CNC machining make it well suited to low volume production for plastic parts.

These setup costs are associated with creating the workpieces and optimizing the number of specific operations required to produce the part. If the part’s geometry is complex enough that rotating or resetting the workpiece or the tools becomes necessary, production cost and time per part will also increase.

However, because CNC machining doesn’t require the creation of expensive molds, manufacturers can begin production far sooner than they can with other processes. CNC machining is highly automated, enabling production both during and outside work hours with minimal input from human workers. What’s more, multiple CNC machines can work from the same design, simultaneously producing identical parts — ultimately shortening production lead times and saving on costs.

CNC machining combines the best of multiple worlds — axial restrictions aside, it can be used to quickly create parts of almost any shape, from any material, and with remarkable accuracy and precision. It’s also a trusted and reliable process, as industries from aerospace and automotive to healthcare and consumer goods rely on components and devices made through machining methods.

At SyBridge Technologies, it’s our goal to make new things possible, and our teams of engineers and designers work tirelessly with every customer to deliver unmatched support during every stage of the production lifecycle. We hold ourselves to exceptionally high standards, guaranteeing that every customer is satisfied with the quality, cost, and production time of their parts. Contact us today if you’re ready to get started on an order.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…