Originally published on fastradius.com on July 18, 2019

Chances are you’re within arm’s reach of something manufactured with plastic injection molding. Highly reliable and efficient, plastic injection molding is one of the most cost-effective methods for producing large numbers of precise, consistent components. From the cover of remote controls to surgical instruments used in hospitals, from water bottle lids to interior elements of airplanes, plastic injection molding is used to manufacture billions of products every year.

First developed in 1872 by two brothers seeking an alternative to ivory in the production of billiard balls, the process has grown more sophisticated over the last 100 years, taking advantage of technical and material advances to become one of the most versatile techniques for mass production. At its heart, it remains an elegant and simple process. Thermoplastic pellets are heated to a liquid state, injected into a mold, allowed to cool in place, and then ejected. While it sounds quite basic, very complex and intricate shapes and products can be manufactured quickly and precisely with very little material waste.

One reason injection molding is so prevalent is that a wide range of materials is available for the manufacturing process, making it possible to fabricate products to strict specifications. For example, a design might call for rigidity or flexibility; UV stability; heat, chemical, impact, or fracture resistance; flame retardancy, or bio-compatibility. Hardness and weight are also considered, along with material cost. Designers and engineers take advantage of combinations and customizations to create unique parts to meet highly complex or unusual application needs.

The six most commonly used materials in plastic injection molding are:

There are thousands of variations within each of these materials, allowing the perfect plastic to meet the needs of the design. Each material has its strengths and weaknesses. For example, Polycarbonate has excellent impact strength, clarity, and optical and mechanical properties. It is not, however, resistant to chemicals and solvents. ABS (Acrylonitrile Butadiene Styrene), often combined with polycarbonate, has mechanical toughness, wide temperature range tolerance, good dimensional stability, and ease of fabrication.

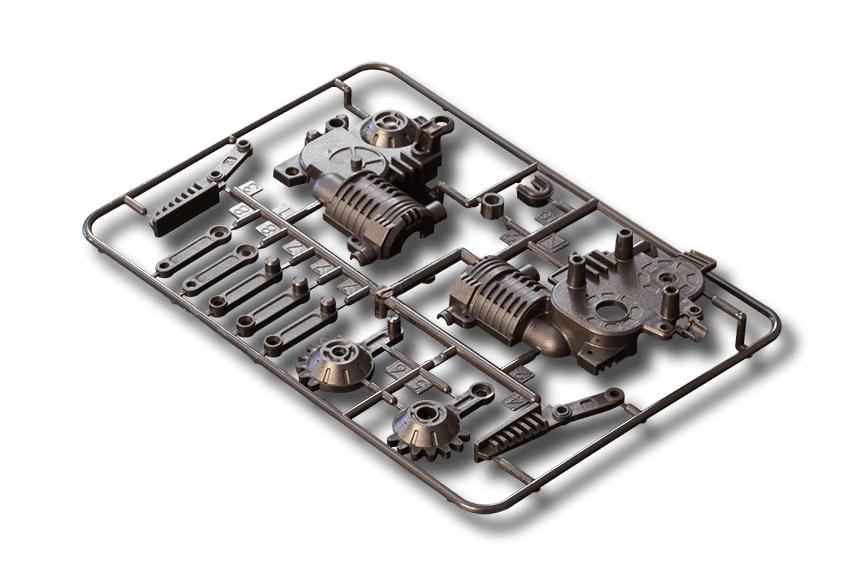

Complex and elegant products made with plastic injection molding rely on well-designed molds, also called tools. Once a product is designed, the tool for manufacture must be designed and built. Many elements are important, such as thickness, rib design, boss design, corner transitions, weld lines, gate placement, and properly located vents. These molds are very expensive; however, once created, they are long lasting and withstand repeated use with only routine maintenance. With low labor costs, minimal post processing requirements, and ability to accommodate high tolerances, the process is effective and efficient for high production runs and producing consistent part quality with very little material waste.

The high start-up costs for plastic injection molding make additive manufacturing technologies an appealing alternative for some projects. Industrial-grade 3D printing can provide low-cost and low risk prototypes of new designs that can be tested and perfected before being put into mass production. Products can be freed from the design constraints of draft angles, undercuts, and other tooling requirements. Without the overhead of tooling, additive can be an economical choice for small volume production. Plus, additive designs can be easily adjusted digitally without having to create costly new molds, making it an attractive option for projects that require customization or serialization. As additive technologies mature to meet the needs of today’s world, engineers and designers are turning to these innovative approaches to develop new products and new models of manufacturing.

It turns out the billiard ball that gave birth to injection molding didn’t take off. Apparently, it didn’t bounce off the rails as its designers had hoped. What did take off was the technology of plastic injection molding, which is now over a hundred years old and agile enough to create billions of versatile products every year. Curious about what type of manufacturing process would work best for your project? Don’t hesitate to contact our team.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…