Originally published on fastradius.com on June 16, 2021

Plastic CNC machining is a subtractive manufacturing process in which a solid block of plastic is placed against a moving cutting tool that removes material from the block. The cutting tool follows a set tool path, guided by a digital design file, in order to shape the final part. CNC machining is a popular manufacturing method for creating plastic components. With this manufacturing process, you can quickly create thousands of uniform and precise parts with incredibly tight tolerances.

You can make many different types of plastic parts using CNC machining, including:

Based on the CNC machining method — CNC drilling, CNC turning, or CNC milling — engineers must adhere to different guidelines to produce superior plastic CNC machined parts. In this article, we’ll break each of them down.

CNC turning involves holding a plastic piece in place on a lathe, which is then rotated against the cutting tool in a spinning or turning motion. There are many different forms of CNC turning, each with its own unique purposes and results. For instance, straight or cylindrical CNC turning is best for large cuts, while taper CNC turning creates a distinct cone-like shape.

Specific guidelines for creating plastic parts with CNC turning machines include:

For rough cuts, we recommend using a feed rate of 0.015 IPR. For more precise final cuts, we recommend a feed rate of 0.005 IPR. Product teams should also know that clearance angles, rake angles, and side angles will change depending on the material used in CNC turning.

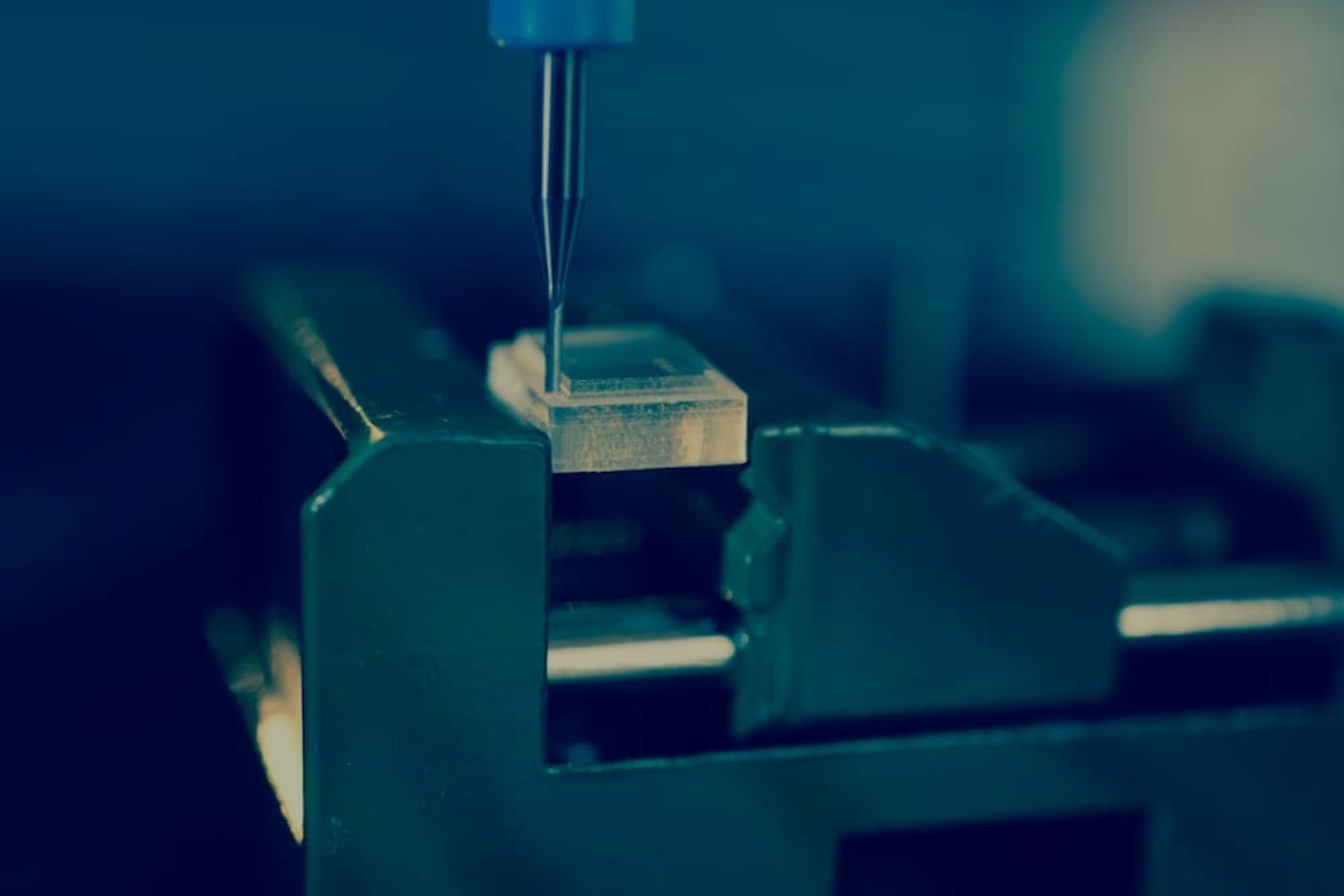

CNC milling is a computer-controlled milling process that uses a cylindrical rotating tool, called a milling cutter, to remove material from a solid workpiece and reveal a finished part. CNC milling machines can be broken down into two broad categories — 3-axis mills and multi-axis mills. 3-axis mills move the cutting tool or the workpiece along three linear axes — left to right, back and forth, up and down — and are best for creating simpler designs. Multi-axis mills, including milling machines with four axes or more, are best for creating plastic parts with complicated geometries.

Specific guidelines for creating plastic parts via CNC milling include:

Creating rounded internal corners and pockets with end mills to mitigate stress concentration

CNC drilling involves using a drill bit to drill holes into a plastic block. A spindle, which secures the block and CNC drill, lowers onto the block and then drills the appropriately-sized holes. There are multiple kinds of drill presses you can use with a CNC drilling machine, including upright, bench, and radial CNC drill presses.

When you’re creating plastic components via CNC drilling, it’s critical that you keep CNC drill bits sharp. Dull or incorrectly shaped drills can put too much stress on the part, causing tooling problems and performance issues. For most thermoplastics, we recommend using a 90 to 118° drill bit with a 9 to 15° lip angle. If you’re drilling with acrylic, you should use a 0° rake.

The ejection of the CNC drill is also essential as poor chip ejection can cause friction and build heat. Since CNC drilling generates more heat than any other CNC machining process, heat reduction is critical to minimizing stress and damage. To safely remove a CNC drill without damaging the part, try to make sure the drilling depth isn’t more than three or four times the drill diameter and reduce the feed rate when the drill has almost exited the material.

Following the guidelines in this article can help you successfully create plastic parts with CNC drilling, turning, and milling. But keep in mind that these guidelines are just that — guidelines! Depending on the complexity of your project, you might need to adjust these guidelines to suit your specific manufacturing requirements.

A seasoned manufacturing partner like SyBridge can help you make the right decisions when it comes to plastic CNC machining. Our team can give you expert advice throughout the entire manufacturing process, taking all necessary guidelines into consideration. At SyBridge, we’re committed to helping you produce the best possible CNC machined plastic part. Ready to take your project to the next level? Contact us today.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…