In today’s competitive landscape, manufacturers are constantly seeking ways to streamline their processes, reduce costs, and increase output. At SyBridge, we understand these challenges and are dedicated to partnering with you to achieve your manufacturing goals.

Our expertise in design, engineering, and tooling for injection molding goes beyond simply creating high-quality molds. We are your strategic partner, offering expert guidance to optimize your entire process, resulting in measurable improvements to your bottom line.

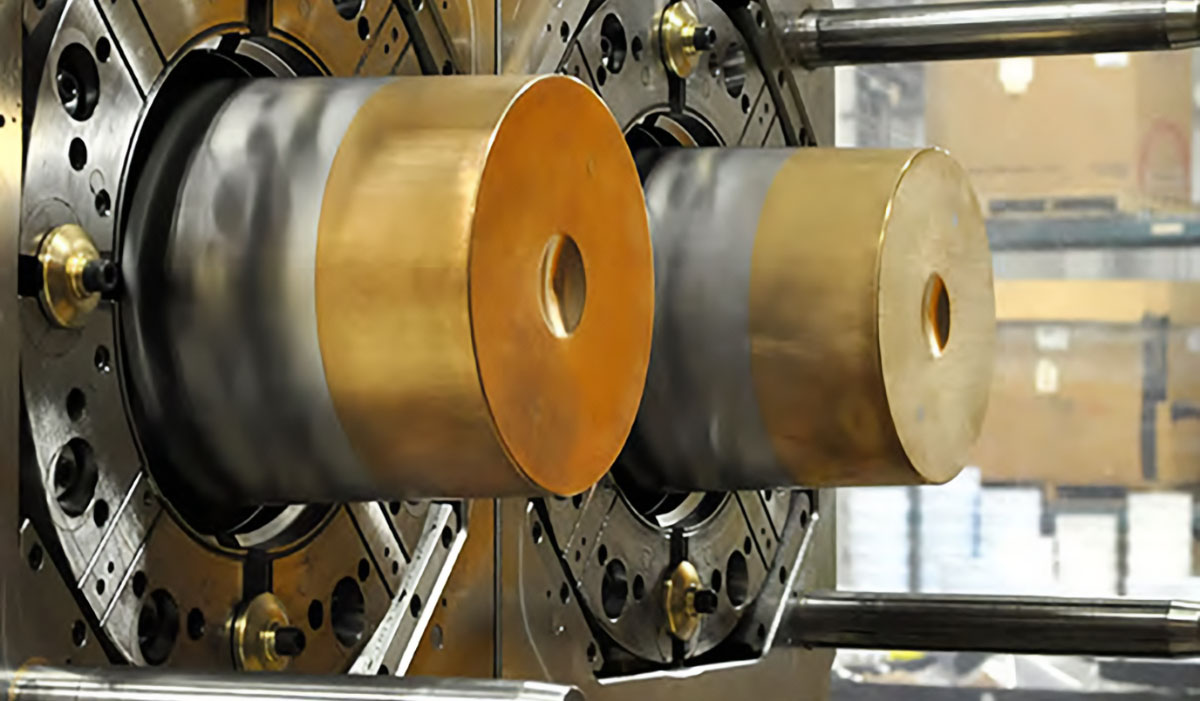

A recent collaboration with a client perfectly exemplifies the value SyBridge brings to the table. We were tasked with re-engineering an existing pail mold. The original design presented several challenges, including:

Our team of engineers meticulously analyzed the existing mold and identified optimization opportunities. By leveraging our expertise in precision tooling and complex high-cavitation tools, we were able to:

The Impact

These improvements translate into tangible financial benefits for our client. They were able to:

Beyond Efficiency

It’s important to note that these improvements were achieved while maintaining the product’s critical performance requirements. The new mold design successfully met all drop testing, shipping testing, and leak testing specifications, ensuring product integrity without compromising efficiency.

SyBridge

This case study is just one example of how SyBridge’s expertise can help manufacturers optimize their injection molding processes and achieve significant cost savings, increased output, and improved profitability. Our commitment to precision engineering, innovative solutions, and collaborative partnerships makes us your ideal partner for navigating the ever-evolving landscape of injection molding.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

How SyBridge Expertise Optimizes Your Process and Lowers Costs In the fast-paced world of manufacturing,…