Originally published on fastradius.com on July 19, 2021

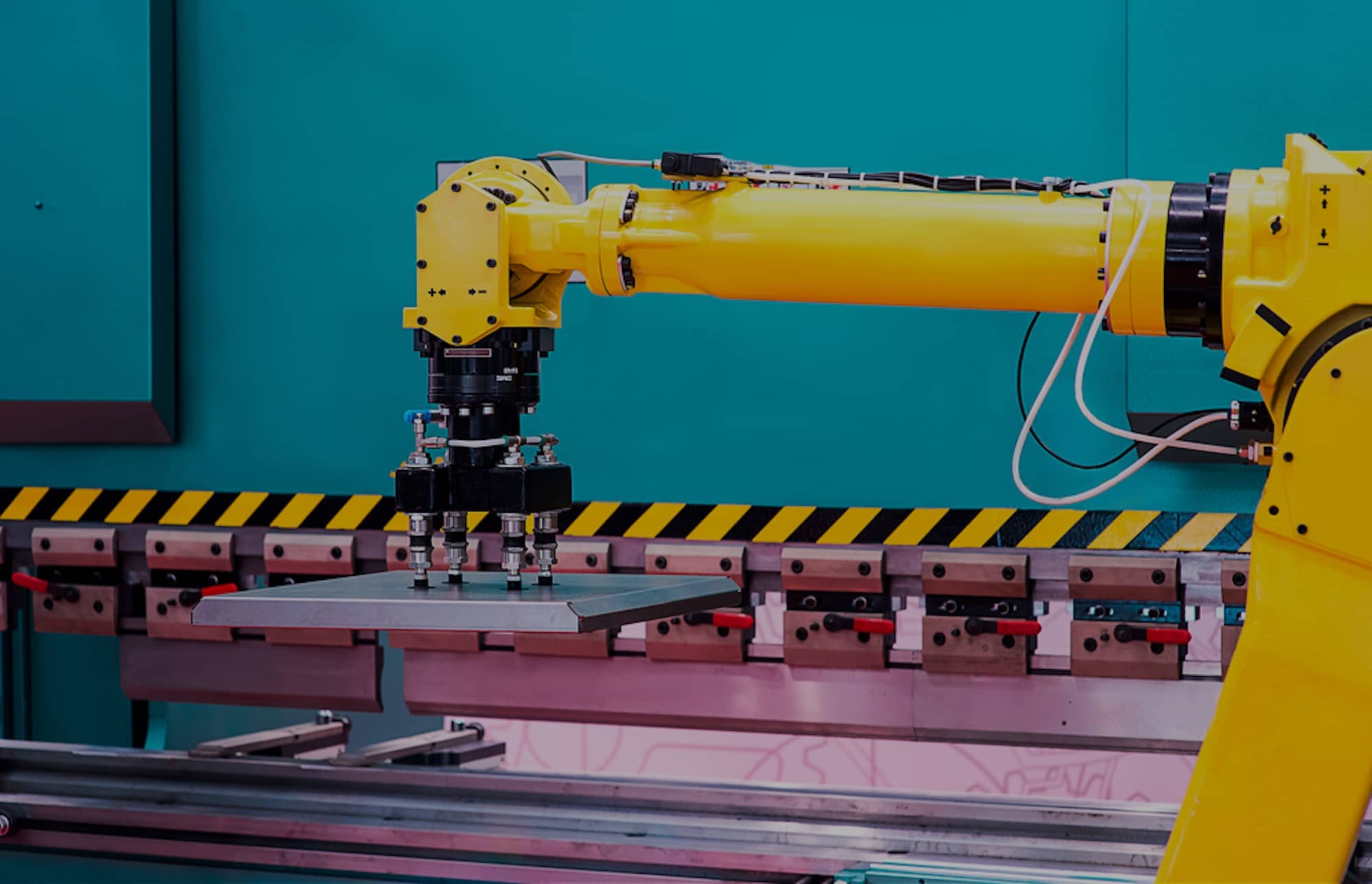

To say that the effects of the COVID-19 pandemic have been wide-reaching is an understatement. Few industries have gone untouched by the COVID-19 pandemic, the manufacturing sector included. While many sectors were already embracing the advantages of Industry 4.0 prior to the pandemic, the past years have seen the dramatic rise of automation in manufacturing.

Faced with the pandemic and global labor shortages, many manufacturers found themselves with empty plants or staggering work shifts due to lockdowns and social distancing protocols. This led them to incorporate smart technologies, remote monitoring, real-time data collection, and automation in their production processes as a means of offsetting hiring challenges while increasing the productivity and efficiency of their teams.

The benefits of automation in the manufacturing sector are likely to last even after the pandemic subsides — savvy manufacturing partners know that leveraging automation whenever possible is key to staying ahead of the competition and optimizing their business processes. This article will explore what automation can look like in the manufacturing industry and highlight the key benefits of partnering with a manufacturing company that knows the power of automation.

The three main types of automation in manufacturing are fixed, flexible, and programmable.

Fixed automation, or “hard automation,” is typically implemented in production environments with high-volume needs and specialized equipment dedicated to set tasks. Generally, most fixed automation solutions are deployed to individual machines, and the sequence of operations the machines carry out is both pre-set and finite.

Fixed automation is ideal for manufacturing high quantities of the same part because the high production volumes involved do not economically allow for equipment and process changeovers. Making alterations to a fixed automation system often requires the machines to be shut down and engineers to change out tooling by hand. This downtime dramatically increases production costs and time. As such, low-volume production runs, parts with changing dimensions or features, and those with shorter lifecycles tend to be better suited to programmable automation systems rather than fixed automation.

Examples of fixed automation solutions include automated assembly machines, machine transfer lines (often used in automotive manufacturing), material handling conveyor systems, painting or coating processes, and more.

Programmable automation systems make it possible to adjust machine configurations and operations using electronic controls. This enables teams to create parts in batches by reprogramming the machines and operation sequences. CNC (Computer Numerical Control) machines are a common example of programmable automation.

An advantage of programmable automation is that the equipment is specifically designed to manufacture a wide range of parts with minimal tooling changeover, which allows batch quantities to vary from as low as dozens of pieces to thousands of parts per batch.

Flexible automation systems are extensions of programmable automation. These highly adaptable systems have four components — part processing machines (typically CNC machining tools), a material handling system, a central computer control system, and human inputs. These systems link multiple machines together via a material-handling system, and human operators input commands through computer code or a Human Machine Interface (HMI), allowing them to manage production and operations from a centralized control board. One key difference between fixed and flexible systems is that the latter is better suited to handle multiple parts at the same time.

Given that the inputs for flexible automation systems change job by job, these systems are often networked, which allows for remote monitoring and controls and eliminates the need for physical proximity between controller and machine. While flexible automation systems can execute tool changeovers automatically without the need for manual intervention, you’ll have to limit part production to those that can be produced with a similar set of tools. Flexible automation is well suited for low- to medium-volume production, jobs with high product variety, and circumstances where changes in demand are expected.

Flexible automation systems are commonly used in chemical processing and the production of common metals like iron, steel, aluminum, and others.

Automation offers manufacturers a wide range of benefits that trickle down to their clients and partners as well.

Robotics and automation can provide far higher efficiency and consistency between parts and across jobs. Automated solutions also help to reduce labor costs by minimizing the need for manual operations while simultaneously increasing workforce productivity — a combination that works in the customer’s favor by lowering part costs and shortening production schedules.

Not only that, more efficient processes and shorter timelines give product teams more time to engage in product design and production, resulting in higher-quality parts. Automation can also help to minimize material waste and remove human error from the manufacturing process, ultimately improving the safety of production processes.

Finally, some manufacturing processes are actually impossible to perform manually. Rapid prototyping and integrated circuit fabrication are examples of many processes that rely on geometric and tolerance requirements that cannot be achieved by hand, making automation essential in these cases.

Given the significant benefits of incorporating automation systems into production, it behooves product teams to partner with a manufacturer that has the right tools and solutions to optimize part design, machine operation sequences, and other processes.

At SyBridge, we believe that cutting-edge technological advancements are the key to improving the quality and efficiency of our work. We have the tools, the technology, and the expertise to ensure that you get a superior part each and every time. Ready to get started? Contact us today.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…