Previously published on fastradius.com on November 16, 2022

Acrylic, also known as plexiglass or polymethyl methacrylate (PMMA), and polycarbonate are both lightweight, transparent plastics suitable for manufacturing parts via CNC machining. Acrylic is known for its strength and transparency, making it an excellent alternative to standard glass, whereas polycarbonate is incredibly tough and impact resistant, making it ideal for applications that require clarity as well as increased durability, such as safety glass.

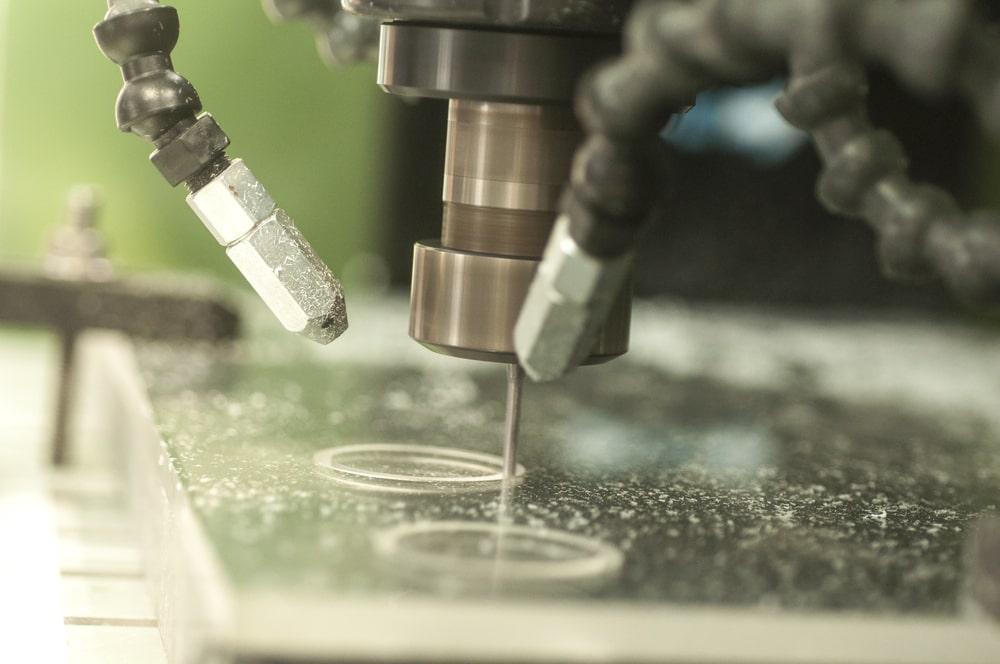

While acrylic and polycarbonate are similar in many respects, there are some important differences between these two common materials that can make one better suited for a particular application over the other, or impact the machining process and thus lead time and cost. In this article, we’ll go over what you need to know about machining acrylic and polycarbonate so that you can select the best manufacturing option for your project and create designs that work with the material you choose.

When it comes to machining acrylic, cast acrylic is often a better choice than extruded acrylic, as the latter is more likely to crack or chip during the machining process. This means that the toolpath strategies sometimes need careful selection to avoid chipping the part. Additionally, since acrylics aren’t very heat resistant, it’s necessary to use a sharp cutting tool in order to obtain a smooth surface finish. Acrylic’s low melting point means that it will also be necessary to use a lower cutting feedrate than other plastics during machining, since higher feedrates will generate more friction and heat, and potentially ruin your part. If necessary, acrylic may be kept in a freezer before machining to ensure that it remains as cool as possible.

With its toughness and impact resistance, polycarbonate is better for machining and is particularly well-suited to CNC milling. However, when machining polycarbonate, the sharpness of the cutting tool is still important, as polycarbonate sheets can melt if too much heat builds up during the machining process. Since polycarbonate is less likely to chip than acrylic, it tends to be easier to machine and allows for more standard toolpath strategies to be used. In addition, because there is a higher temperature working range, more aggressive strategies can be used with a smaller chance of causing issues, potentially saving time and money.

Both acrylic and polycarbonate are lightweight, machinable, and have unique characteristics that make them suitable for an array of applications across industries.

Acrylic is a popular material within the automotive, construction, and aerospace industries, and is often used for things like dry boxes, lenses, radiation shields, and desiccators. Additionally, its transparency, strength, and high impact resistance make it a great alternative to glass, and you can commonly find it used in greenhouses, aquariums, terrariums, security barriers, and more.

Like acrylic, polycarbonate is popular in the automotive, aerospace, and construction industries, but its resistance to heat and strong dimensional stability make it very popular in the medical industry, as polycarbonate parts can withstand limited autoclaves and irradiation sterilization. Among its more common applications, polycarbonate is often used for point-of-purchase retail displays, face shields, architectural features, clear manifolds, bulletproof windows, and much more.

Acrylic offers a range positive attributes, including:

CNC machining acrylic is not without its disadvantages. As previously noted, acrylic is more susceptible to cracking and chipping than polycarbonate, and it’s slightly more difficult to machine, since it will lose structural integrity and begin melting at temperatures over 160°C. When designing acrylic parts for CNC machining, you’ll need to remember that relatively low melting point because it makes the material more susceptible to deformation during the manufacturing process. To avoid the risk of melting, and to achieve a quality surface finish, using a proper feed rate and pass depth is crucial. Similarly, to reduce chatter and achieve quality cuts, acrylic parts should be machined using tools with a short flute length and a cutting depth roughly half the diameter of the bit.

Your product’s intended use will also determine whether acrylic is the best option for your project. For example, acrylic’s extreme biocompatibility makes it a good option for bone implants, dentures, or other skin-contact applications; similarly, its resistance to weather, UV radiation, and scratching make it a good fit for parts which will be used outdoors. On the other hand, acrylic might not be the best choice for food containers that will be exposed to high temperature environments, such as dishwashers or microwaves, since acrylic parts will only maintain their dimensions up to 149°F (65°C), at which point they begin to soften.

The positives of using polycarbonate include:

While polycarbonate has many positive attributes, there are some disadvantages to using polycarbonate for a CNC machining project, including its high cost and its susceptibility to denting. Additionally, since polycarbonate scratches easily, it’s more likely to require finishing, which is complicated by the fact that only certain finishing processes, such as vapor polishing and coating, work with polycarbonate parts.

Additionally, it’s important to note that polycarbonate parts are also prone to developing sinks or voids in thicker sections. To prevent this, it’s best to break thicker elements down into smaller, thinner sections to be assembled later. It’s easy to remember this tip by keeping costs in mind — machining a thick part out of a single block of polycarbonate will typically be more expensive than working with smaller pieces due to the cost of the raw materials and the machining time.

There are several finishing options available for acrylic and polycarbonate, including some that will help your parts look and feel ready for end-use applications and even improve clarity:

With sufficient care during the cutting process, machined surfaces of acrylic and polycarbonate parts will typically be translucent, but can become nearly opaque if the material melts. Should melting occur, it may be possible to address surface opacity with post-processing options such as vapor polishing. However, it’s worth noting that as-machined finishes for acrylic and polycarbonate parts will not be optically clear, although it may be possible to achieve optical clarity if diamond tooling is used, but this must be specifically requested during the quoting process, as it will significantly add to cost.

Special care should be taken with designs that include machined acrylic due to the increased likelihood of stress cracking. With this in mind, it’s advisable to use razor-sharp cutting tools to avoid melting the acrylic or causing cracking; diamond cutters yield the best surface finish, though carbide cutters are much more affordable. It will also be necessary to use a relatively fast feed rate to prevent the acrylic from melting, but remember that going too fast can cause extreme cutting pressure and breakage.

While polycarbonate is generally better suited to machining thanks to its rigidity, toughness, durability, and higher melting point, the trade-off is that polycarbonate is less transparent than acrylic. However, if you need to create specific-use parts, such as protective gear, fuse boxes, or large, tough components, transparency may not be an issue. On the other hand, if you’re designing a product for which transparency is a top priority, taking the extra effort to machine acrylic may be worth it.

Selecting a suitable material for your manufacturing project can be the difference between success and failure. While we’ve explored the positives and negatives of acrylic and polycarbonate, it’s worth remembering that they’re not your only options. Numerous CNC machining materials may be compatible with your part’s design and intended application, and choosing the right one can be a complicated process.

Fortunately, a manufacturing partner like SyBridge can reduce that complexity and address the challenges certain materials present. Beyond helping you decide whether acrylic, polycarbonate, or another material will work best for your part, our team can offer access to the tools and expertise you’ll need to ensure production runs as smoothly and cost-efficiently as possible. And getting your project started is simple: just create an account and upload your designs to get a quote for your parts instantly. Or, to learn more about how we can make your project possible, contact us today.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…