Originally published on fastradius.com on July 6, 2022

Injection molding involves injecting molten plastic into a mold, cooling it, and ejecting it. Manufacturers can repeat the process to quickly and cost-efficiently to create thousands of identical parts.

Several subprocesses fall under the general umbrella of injection molding, including insert molding and overmolding (a.k.a. multi-shot injection molding, two-shot injection molding, or double-injection molding). Keep reading to learn the differences and similarities between insert molding and overmolding, their applications, and how to figure out which type of multi-material molding is best suited for your project.

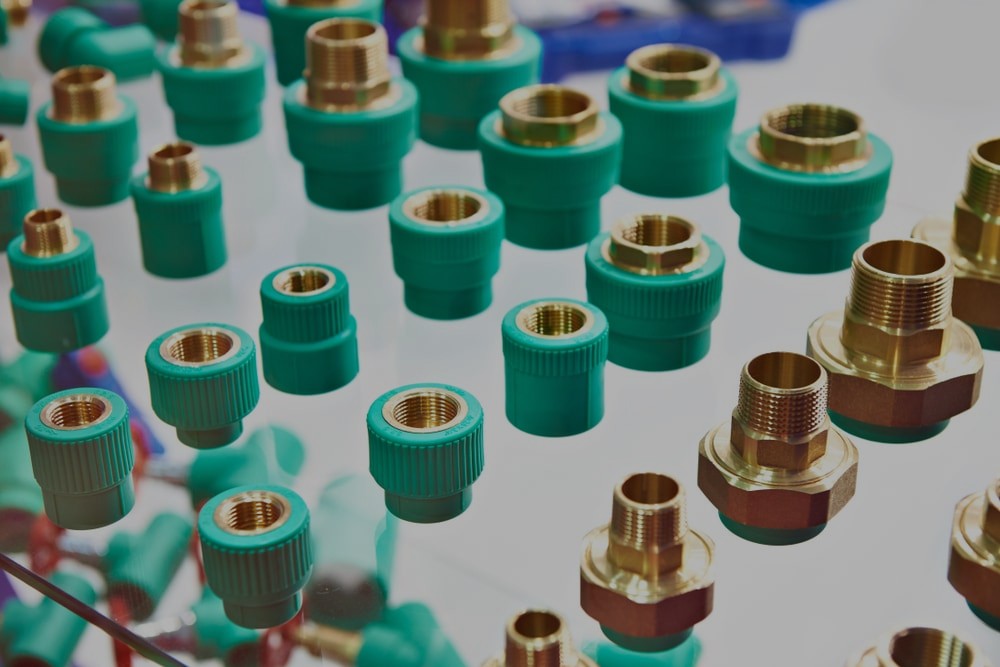

The insert molding manufacturing process involves injecting molten plastic around pre-placed inserts (usually metal), forming a strong bond between the two materials and helping cut back on assembly operations and time. Common inserts include pins, blades, threaded nuts and knobs, sleeves, bushings, and the metal shanks of tools, such as screwdrivers.

Overmolding enables manufacturers to create parts from multiple materials using a manual two-stage process for small production runs or an automated two-stage process for large production runs. Regardless of production volume, the overmolding process works in the following way. First, a thermoplastic injection forms the rigid substrate. After the substrate forms, another shot (generally thinner and more pliable) is injected in, on, or around the substrate. As the materials cool, they bond together, creating a unified, strong, and durable part. Bonds can be chemical or mechanical, depending on the materials as well as the design of the part or product.

Overmolding and insert molding enable manufacturers to create multi-material products without using adhesives, help eliminate secondary assembly steps, and improve the final product. However, it’s important to note the differences between insert molding and overmolding, including:

Overmolding involves injecting two shots of materials to form the substrate and the overmold. Insert molding only involves injecting one shot of molten plastic, though the metal insert needs to be purchased or created separately.

Insert molding involves one shot while overmolding involves multiple, which means the insert molding cycle time is generally faster than the overmolding cycle time. However, that doesn’t necessarily mean that insert molding is always the fastest option for production. In some cases, manufacturers may be unable to find pre-made metal inserts that meet their requirements, meaning they’ll need to create a custom metal insert, which can lengthen production timelines.

Insert molding and overmolding can reduce assembly costs and accelerate production, helping companies simultaneously save on production costs and generate greater profits when producing large quantities of parts. However, overmolding is more expensive than insert molding, as it involves two steps. This is particularly true when it comes to prototype or small production runs, as overmolding requires manufacturing two tools — one for the substrate and one for the overmold.

Overmolding is often used to make toothbrushes, medical instruments, disposable razors, and phone cases, or to enclose electronic circuit boards (e.g. USB flash drives).

On the other hand, insert molding is a popular option for connectors, dash panels, electric sockets and wires, dials, remote control coverings, handles, scissor grips, and surgical implements.

Insert molding and overmolding are both types of multi-material injection molding, but they each have their own benefits and drawbacks and can’t be used interchangeably. To ensure you use the best process for your part, you’ll need to be familiar with each method. If you need some help selecting the best technique to use, contact us to get expert advice on your next injection molding project.

In addition to a team of experts that will help you make your design reality, when you work with SyBridge, you also get access to a suite of online tools that makes designing and ordering parts easy. You can upload your part file, get DFM analysis, and start exploring production and material options, all without initiating a quote — and when the time comes, getting a rapid quote is simple. Contact us today to get the design and manufacturing insight you need to bring your next injection molding project to life.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…