Originally published on fastradius.com on July 25, 2022

To complete your production run on time and on budget, it’s best to have a clear picture of your expected project costs from the very beginning. However, predicting accurate CNC machining project costs is easier said than done for many product teams. You’ll need to consider material costs and machinability, your part’s complexity, post-processing requirements, and the actual CNC machine setups. Let’s explore the effect CNC setups can have on production costs.

Depending on the complexity of your design, your CNC operator might need to use multiple CNC machine setups to manufacture parts with features on several sides, planes, or axes. To machine these features, your operator will need to remove your part from the machine and flip it over to work on the other side or move it to a different CNC machine setup to finish the production process. They’ll also need to recalibrate the fixture and tools each time. Plus, the longer it takes to machine a part, the higher your project costs will be.

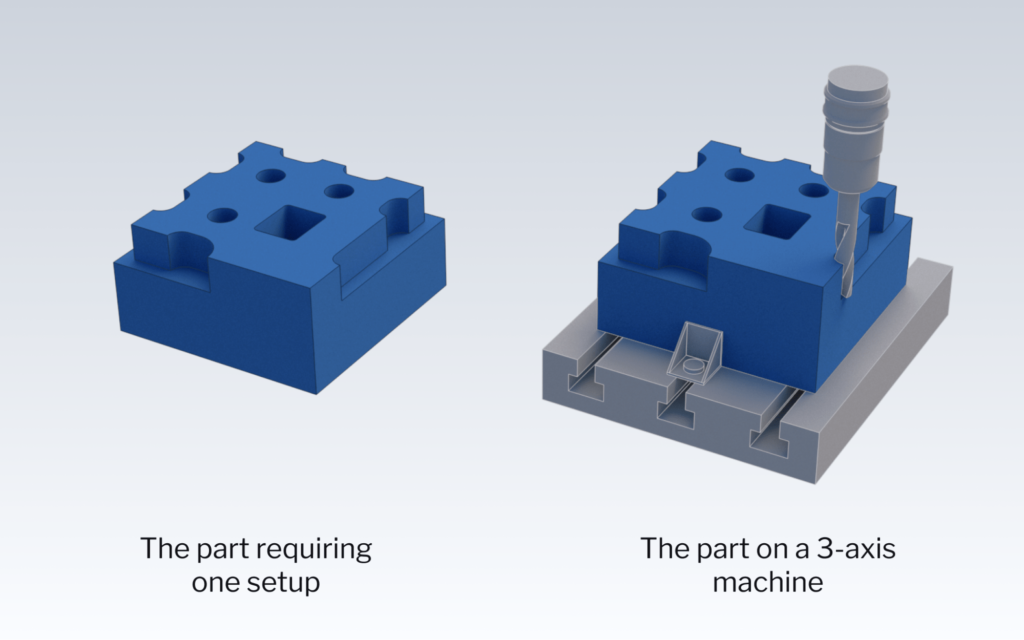

A part that only needs one setup on a 3-axis milling machine will require only one face to have access for the tool, as seen in the image below.

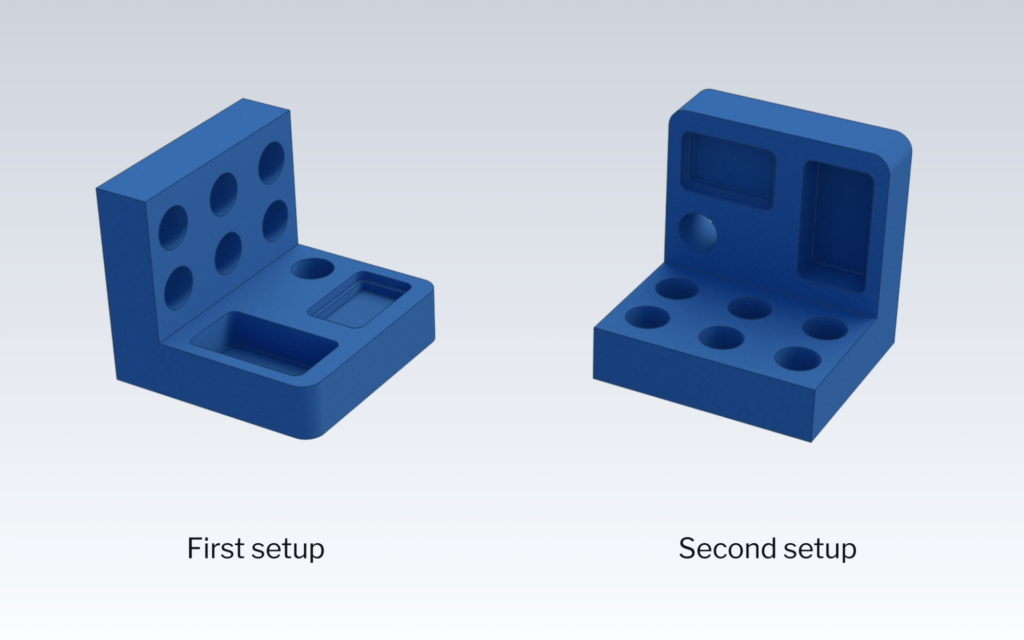

A part that needs multiple setups on a 3-axis machine will have multiple faces that require access, like the part below.

When identifying if a part will need multiple setups to machine, consider how the tool will access all of the different features in the design.

There are a few additional cost drivers to keep in mind when it comes to any CNC setup, including:

Every part and every project is different, so it’s difficult to attach a definite number to how CNC setups increase project costs. However, the more setups you have, the more time your operator will spend resetting the CNC machine, recalibrating tools, and designing new fixtures, all of which can raise the cost of your project.

It’s also important to note that the number of setups isn’t the only driving factor behind setup costs. For example, if you use an exotic or hard-to-machine material, your operator will need to work more slowly with your CNC setup, lengthening machining times and increasing material costs. Using non-standard tooling and running the CNC machine on unoptimized toolpaths can also make your project more expensive.

Product teams looking to maximize their budgets and make CNC machining more cost-effective can make an impact by keeping the above points in mind.

Making a few smart decisions behind the scenes can lower your overall project costs. To reduce CNC machining costs as much as possible, consider:

One of the easiest ways to drive your cost-per-part down is to order more parts. If your manufacturing partner uses an expensive CNC tool and fabricates a custom fixture to bring a complex design to life but only manufactures a few parts, each part would cost a significant amount of money. Manufacturing a larger number of parts using that same tool and fixture more evenly distributes those costs and allows the manufacturer to purchase raw material in bulk at a lower cost, which together can significantly lower the cost per part.

Several factors can determine what material you choose for your project, including strength, machinability, cost, and availability. Remember that exotic materials are costly and metals are typically more expensive than plastics. As a general rule, consider using a common aluminum instead of a more expensive metal when possible to lower your overall CNC costs.

You’ll also want to consider material machinability, as less-machinable materials drive up manufacturing costs. Exotic materials often require expensive specialized tooling, and materials that require slower machining speeds mean longer manufacturing times and increased machine operating costs. Whenever possible, opt for materials like low carbon steel and aluminum because they are faster, easier, and cheaper to machine.

Also, look for materials that are already similar in size and shape to your part. This ensures you aren’t wasting money machining away a lot of excess material, and it also reduces machining time.

As with most things, customization costs more. Tooling, blanks, and other objects typically come in standard sizes such as whole numbers and fractions in multiples of two (i.e. ¼, ⅛, etc.). If you design a feature that requires a drill with a 0.265-inch diameter, your manufacturer will need to acquire a custom drill bit to meet your requirements. However, if you opt for a more standard tool size, such as 0.25 inches, the standardized tooling your manufacturing partner has on hand will suffice. Similarly, using standard raw material blanks, jigs, fixtures, and other components instead of custom elements can help cut costs and accelerate production.

If using a standard fixture would block tool access, however, creating a custom fixture to avoid multiple setups makes sense. Fortunately, you can use additive manufacturing technology to quickly and cost-effectively create custom fixtures.

Tight tolerances can also drive up manufacturing costs and turnaround times, as your operator will need to machine at a slower pace. They will also need to regularly remove and inspect your part to ensure tolerances are correct, which prolongs the production process and increases overall costs.

Don’t over-tolerance and make sure that the tolerances you set are compatible with what your part actually requires. If you’re creating a consumer product, don’t use the extremely tight tolerances necessary for aerospace parts. Or, if you’re manufacturing a prototype, you should use a looser tolerance than you might for your final product.

Performing design for manufacturing (DFM) checks to identify and correct potential problems before manufacturing can also help keep costs low. Pay particular attention to:

If you notice any of these flaws, you might want to consider redesigning your part. You can also easily check for common DFM errors like those mentioned above by uploading your part to your SyBridge dashboard.

CNC machine setups can significantly impact your overall production costs, but sometimes using multiple CNC setups can’t be helped. The good news is that you can make your project more cost-effective — even if multiple setups are required — by setting reasonable tolerances, designing for manufacturability, and thoughtfully choosing CNC materials. Working with an experienced manufacturing partner like SyBridge can help.

Get started on your next CNC machining project today by uploading your part to for an instant quote or by contacting our team.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…