Originally published on fastradius.com on May 3, 2021

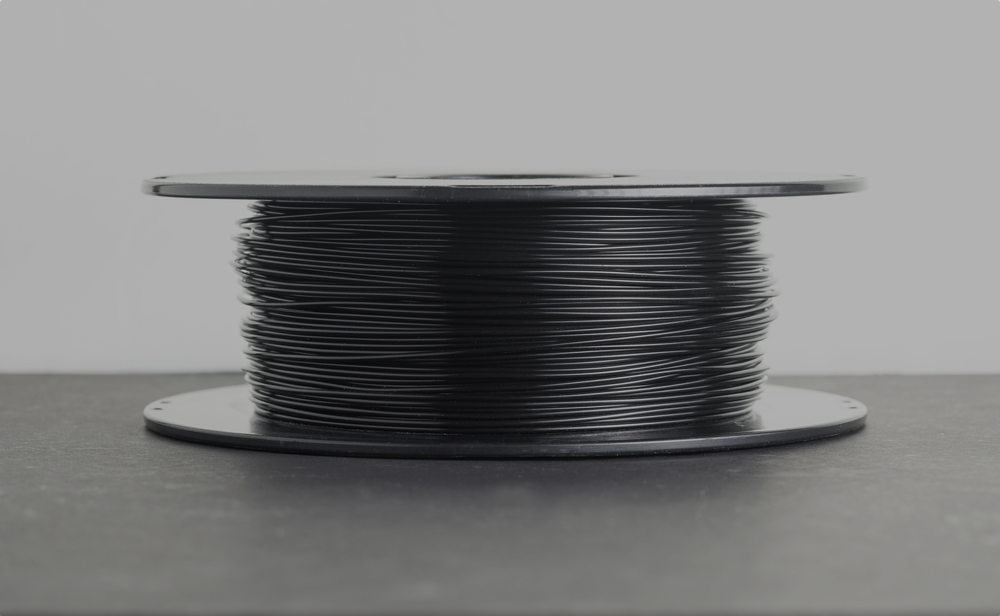

Fused deposition modeling (FDM) is a simple and versatile 3D printing technology that uses molten thermoplastic material to create a finished part. During this process, thermoplastic FDM material is melted inside the heated printing nozzle of the FDM machine and then extruded onto a set toolpath, layer by layer, until the part is formed. FDM is one of the most widely-used additive manufacturing processes available today.

A common misconception is that FDM can only be used for 3D prototyping and modeling. In fact, FDM is often used to create industrial-strength, high-performance parts in the aerospace, automotive, robotics, and electronics industries. Common examples include aircraft interior components, replacement parts for cars, and industrial-grade jigs and fixtures. Manufacturing these high-performance parts wouldn’t be possible without the use of high-performance plastics. Here’s everything you need to know about five of the most high-performing materials used in the FDM process.

ULTEM®, the branded name for polyetherimide (PEI), has been a staple in the manufacturing industry for more than 30 years and remains one of the few commercially available amorphous thermoplastic resins that are specially designed to withstand extreme conditions. Stable and lightweight, this FDM plastic material can withstand temperatures upwards of 217°C for extended periods of time and stay stable in fluctuating temperatures. What’s more, it’s inherently flame-resistant and produces minimal smoke.

ULTEM’s mechanical specifications include:

Due to its strength and durability, ULTEM® is often used for high-performance industrial applications like circuit boards and food preparation and sterilization equipment. Also, since it resists cracking when it comes into contact with fats, oils, alcohols, acids, and other aqueous solutions, ULTEM® is ideal for automotive applications and aircraft parts.

You can find ULTEM® in transmission components, fire blockers, airplane seat covers, and more. For all of its strengths, product teams should know that this FDM material is very expensive and susceptible to cracking in the presence of polar chlorinated solvents.

Nylons are a family of high-performance engineering thermoplastics known for offering excellent strength and stiffness without compromising impact performance. This FDM material can be combined with a wide range of different additives to achieve certain chemical and mechanical properties, making it extremely versatile and applicable to many different use-cases. Nylon 6, a processable and highly elastic filament, is particularly well-suited for industrial FDM applications.

Nylon 6 has high strength at high temperatures, good impact strength at low temperatures, and good fatigue resistance. Plus, its smooth, glass-like surface fibers offer outstanding abrasion resistance. Common applications include industrial cords, electrical moldings, fuel system components, and replacements for metal bearings or bushings. The mechanical specifications for unreinforced Nylon 6 include:

ABS is a strong, rigid, and impact-resistant high-performance engineering thermoplastic. Engineers and product teams like to work with this material because it stays mechanically strong and stable over time, without compromising workability. ABS is very weldable and easy to process using standard machinery, plus its low melting temperature makes it particularly well-suited for processing on an FDM machine. Designers like ABS’ high surface brightness and excellent surface aspect.

Mechanical specifications for ABS include:

Still, this FDM plastic material does have its drawbacks. Even though ABS is resistant to abrasion and impact, it has poor weathering resistance and scratches easily. It also has poor solvent resistance to ketones and esters. Certain greases will cause ABS to stress crack. If you can work around these pain points, however, you’ll find yourself with a strong FDM material for industrial applications. Common uses include pipe fittings, auto parts, and electronic housings.

Polycarbonate is a high-performance, engineering-grade amorphous thermoplastic resin. Stronger than polymethyl methacrylate (PMMA) and more rigid than nylon, this FDM plastic is durable and known for maintaining its coloring and strength over time and in stressful conditions.

PC is lightweight, abrasion-resistant, intrinsically flame-retardant, and thermally stable up to 135°C. It is also resistant to diluted acids, aliphatic hydrocarbons, and alcohols. However, it’s worth noting that PC is sensitive to abrasive alkaline cleansers and aromatic and halogenated hydrocarbons.

From a design standpoint, PC also offers designers a lot of flexibility. This material is highly transparent, can transmit 90% of light as well as glass, and clear polycarbonate has a refractive index of 1.584. PC sheets are also available in a variety of different shades that will suit any aesthetic. To keep FDM transparent material crystal clear, designers should keep an eye out for yellowing after prolonged exposure to UV light. Common applications for this FDM material include safety helmets, bullet-proof glass, car headlamp lenses, medical devices, and electrical components.

Mechanical specifications for polycarbonate include:

Like polycarbonate, PPSF is a tough, transparent, and intrinsically flame-retardant FDM material. With a heat deflection temperature of 274°C and a continuous-use temperature of 260°C, PPSF is ideal for high-performance plastic parts that will be used in high-temperature environments like circuit breakers and aircraft interiors.

PPSF also has good electrical insulating and dielectric properties, high resistance to gamma rays, and a very low rate of water absorption. This material is also physiologically inert, so it’s suitable for food contact.

Mechanical specifications include:

It’s worth noting that PPSF, like ULTEM®, might be prohibitively expensive for some product teams to use. Also, its low clarity can restrict certain design parameters.

Fused deposition modeling is a versatile additive manufacturing process well-suited for prototyping, modeling, and industrial-grade high-performance parts. ULTEM® (PEI), nylon, ABS, polycarbonate, and PPSF are all FDM 3D printing materials that have the strength and heat-resistance to stand up to a range of high-performance applications across many sectors.

Still, these five FDM printing materials are only the tip of the iceberg. There are plenty of other high-performance plastics to choose from and it’s easy for product teams to get overwhelmed by a sea of options. Working with an experienced manufacturing partner makes FDM material selection much easier.

The SyBridge team has years of experience with 3D printing technologies, including FDM 3D printing. Our team of seasoned designers, engineers, and technologists can help you choose the FDM plastic material that’s perfect for your next project — and help optimize the full product development lifecycle. Contact us today to get started.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…