Originally published on fastradius.com on July 7, 2021

Finite element analysis, also known as FEA, is the virtual simulation of a physical component using a mathematical technique called the Finite Element Method (FEM). The roots of FEA date back to the sixteenth century, and the first true use of FEA dates back to Schellback’s work in 1851. For the next hundred years, FEA was primarily used by mathematicians and other scholars. With the advancement of digital computers, real-world developments of FEA began to pop up within the automotive, aerospace, and civil engineering industries.

FEA can now reach more users than ever. Today’s finite element analysis software is intuitive to use, accessible across electronic devices, and incredibly fast and powerful. To discover more about what FEA is and how it works, keep reading.

FEA is the process of creating a digital simulation of a soon-to-be-real product. While finite element analysis once required you to put pencil to paper, nowadays FEA takes place in a computer program’s virtual environment. FEA computer-based software can virtually model complex geometries and components, enabling scientists and engineers to better predict how these products will perform in real life.

In the design and manufacturing process, FEA can help you understand a part’s physical properties — such as its impact resistance, thermal elements, and transient dynamics — to predict its strength, movement, and other behaviors. FEA can also envision the characteristics of a particular material under specific conditions like deflection, vibration, and other stressors. Through these predictions, FEA enables you to identify potential performance issues and find solutions before the component is created.

There are different types of finite element analysis, including:

Finite element analysis is an incredibly mathematical process, so we’ll explain it in layman’s terms. Simply put, FEA breaks down a complex structure into smaller and more manageable portions. As you split the structure into smaller sections, you will gain more knowledge of how the larger structure will respond to stressors.

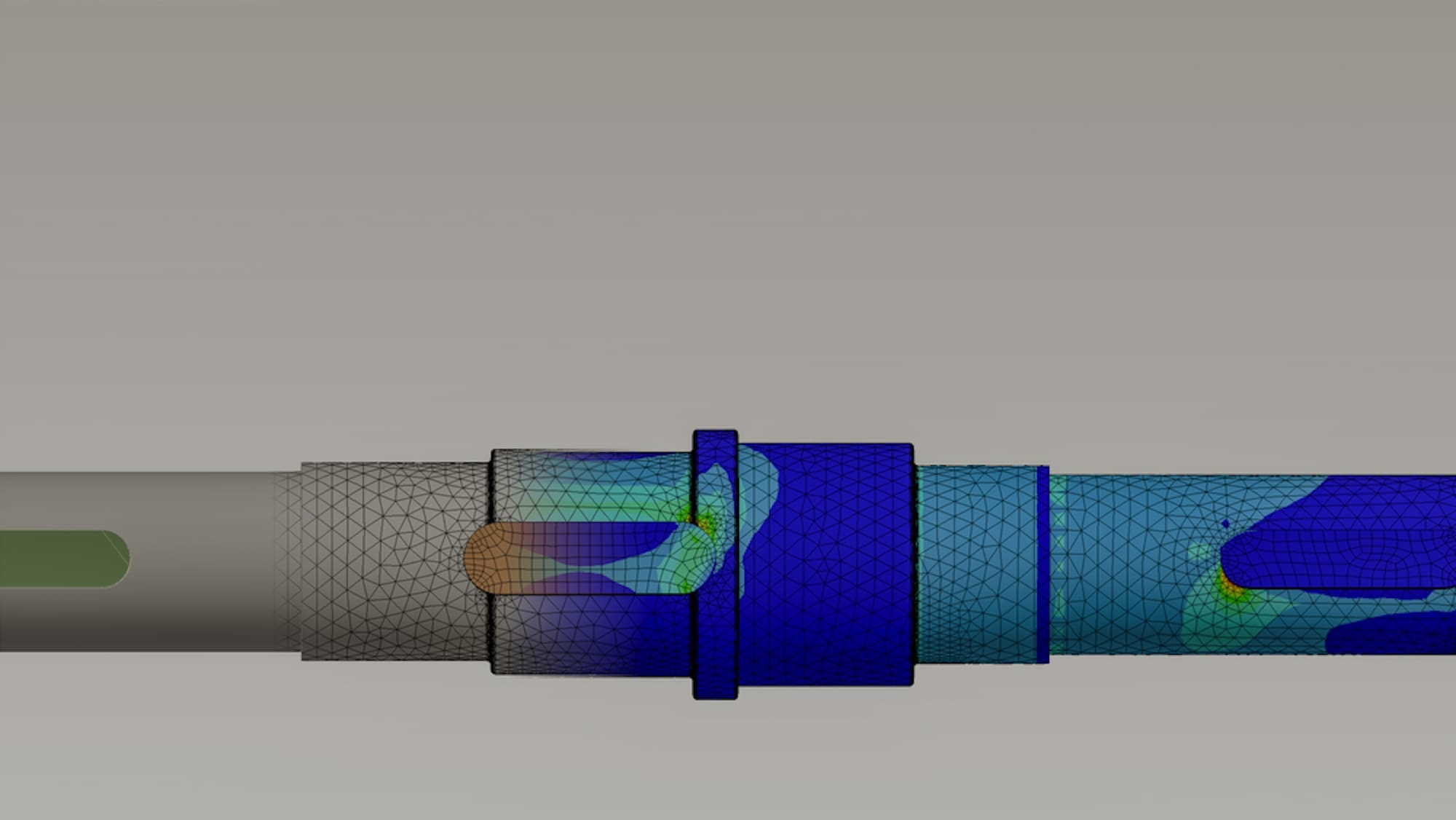

The first step of the FEA process is to determine the placement of nodes on the structure, which are single points on a 2D or 3D rendering of your design. After selecting your nodes, or nodal points, connect them by drawing lines between them. This will create a mesh structure that forms the final shape of the design. The regions enclosed by the mesh contain a collection of finite elements, which is where the name “finite element analysis” comes from.

By tackling the small sections that make up your structure’s mesh, you can more precisely determine how the entire structure will act in given circumstances. Note that the more dense your mesh structure, the more precise your results will be, but your computations will increase in complexity as you add nodal points.

In manufacturing, FEA is used to determine a component’s potential responses to external and internal physical stressors. Finite element analysis software is built to take part geometry, material, environment, and other factors into account when virtually testing your FEA simulation. This enables you to predict how a component will perform under expected and unexpected conditions.

Since FEA exists in a virtual world, it can significantly streamline the prototyping process. Instead of having to build prototype after prototype, FEA enables you to easily test a component many times and make changes between iterations. This saves you time, resources, costs, and effort when designing a component. FEA software is designed to be as realistic as possible, enabling these powerful programs to accurately anticipate part performance.

Rapid virtual prototyping supported by FEA is especially important in the aerospace industry. Because aerospace components must survive the extreme stress of outer space — such as air pressure, inertia, impact forces, and super-high heat — it’s critical that they follow very strict manufacturing guidelines. Using FEA, you can accurately anticipate how a component will react to these extreme conditions. FEA can also predict years or even decades of use, a helpful tool for aerospace components that could be in orbit for many years.

Throughout the manufacturing process, FEA allows you to save time and money, reduce energy and material waste, and gather instant and accurate feedback on how physical stress could affect your component. Overall, FEA contributes to a quicker, less intensive design cycle with increased productivity.

Finite element analysis is a specialized field. At SyBridge, we have experts on hand who will use FEA to optimize your part designs. By leveraging accurate finite element analysis, our team can help you improve your parts and perfect your production runs. Contact us today to get started with FEA.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…