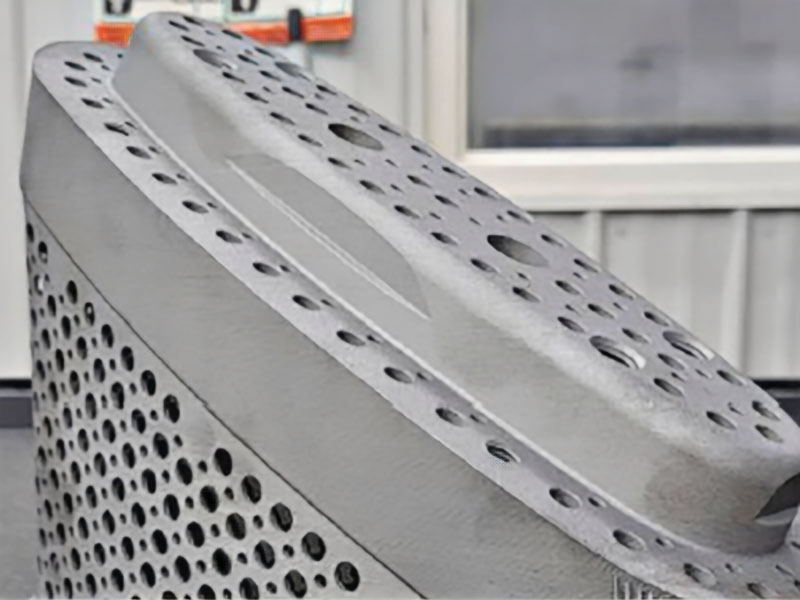

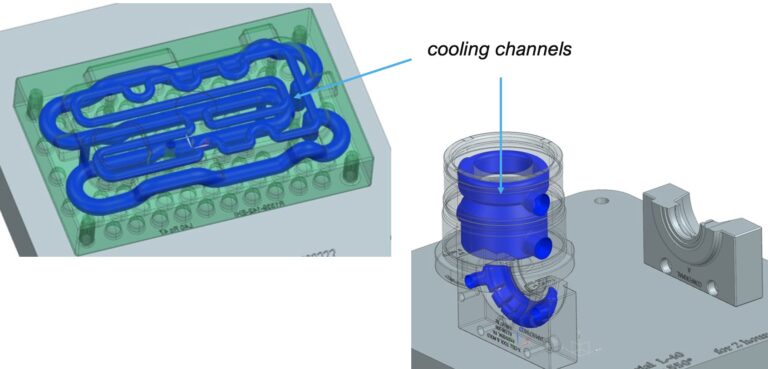

A common challenge when designing parts for injection molding is factoring in cooling rates for distinct areas within a part’s design. In order for the mold to eject the part properly, of course it must be cooled. However, with high-volume or geometrically-complex parts, certain areas of the part may cool at different rates, resulting in longer cycle times and the potential for warpage. To avoid these issues and increase the productivity of the mold, parts can be designed with integrated conformal cooling channels that will allow water to access the deeper areas within the part, providing more even cooling, reducing the cycle time and the occurrence of defects. These approaches have existed for some time, but advances in metal 3D printing has enabled new conformal cooling geometries and resulting solutions to tool makers.

During the molding process a part cools from the exterior surface to the inner core of the plastic, ideally at the same rate for all areas of the part when it is designed with consistent wall thickness. When injection molding simple, uniform parts conventional cooling typically doesn’t pose any challenges, as all areas of the part generally cool at a similar rate.

However, if a part design is geometrically complex, then the part may not cool at an even rate in all areas, resulting in potential warpage or longer cooling cycles to ensure solidified parts before ejection. The truth is that in today’s world with increasingly complex part geometries, perfectly uniform cooling rates are difficult to attain. In the case of low volume runs, the inefficiencies of having a slightly longer cooling cycles can be negligible and tolerable for molders. However, in the case of high volume runs, these efficiencies can be opportunities to improve productivity or reduce waste. The resulting efficiency of conformal cooling depends on many factors, from the design of the cooling channels, the design of the part, the mold design and even the molding recipe. When done properly, conformal cooling solutions can improve tooling output by 50% or more.

Including conformal cooling channels in the mold tooling will help address hot spots that result in warpage, resulting in better quality parts with less material waste and fewer defects.

In addition to achieving a better quality end result with a lower risk of defects, conformal cooling channels often significantly decrease mold cycle times. In the example below, conformal cooling was used to reduce the cycle time of this high-volume plastic component by almost 40%, increasing mold productivity by nearly 50%.

Including conformal cooling channels in injection mold tooling is popular across industries and product types, particularly in the life sciences, and consumer products sectors where parts with complex geometries or high mold volumes are common. If you plan to produce a large volume of parts via injection molding and are concerned about warpage, designing your injection mold tooling with conformal cooling may be the right solution to help with cycle times and lower part costs. In order to ensure that the channels are properly designed for your part’s geometry and specific application, it is imperative to work with an experienced tooling designer who is knowledgeable about how to integrate these novel approaches into high precision tooling.

At SyBridge, our engineers are experts in the injection molding and tooling design processes, and have worked with companies across diverse industries to help them achieve incredible results when it comes to improving mold productivity, reducing defects, and producing higher-performing parts. Whether you already have a mold design that you believe would benefit from the addition of conformal cooling channels or you’re working on the design for a new part or product, our team is here to help.

Contact us to speak with an injection mold tooling design expert and discover if conformal cooling is right for your injection mold tooling needs.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…