Originally published on fastradius.com on February 20, 2021

Engineers and product teams have many options for metal fabrication. Depending on the part design and the use-case, cutting, folding, shearing, or stamping — just to name a few — may be appropriate.

Among the most widely employed metal manufacturing methods are Computer Numerical Control (CNC) machining and die casting, which share certain similarities but also have some key differences to keep in mind. Here’s everything that product teams should know before selecting either CNC machining or die casting for their next project.

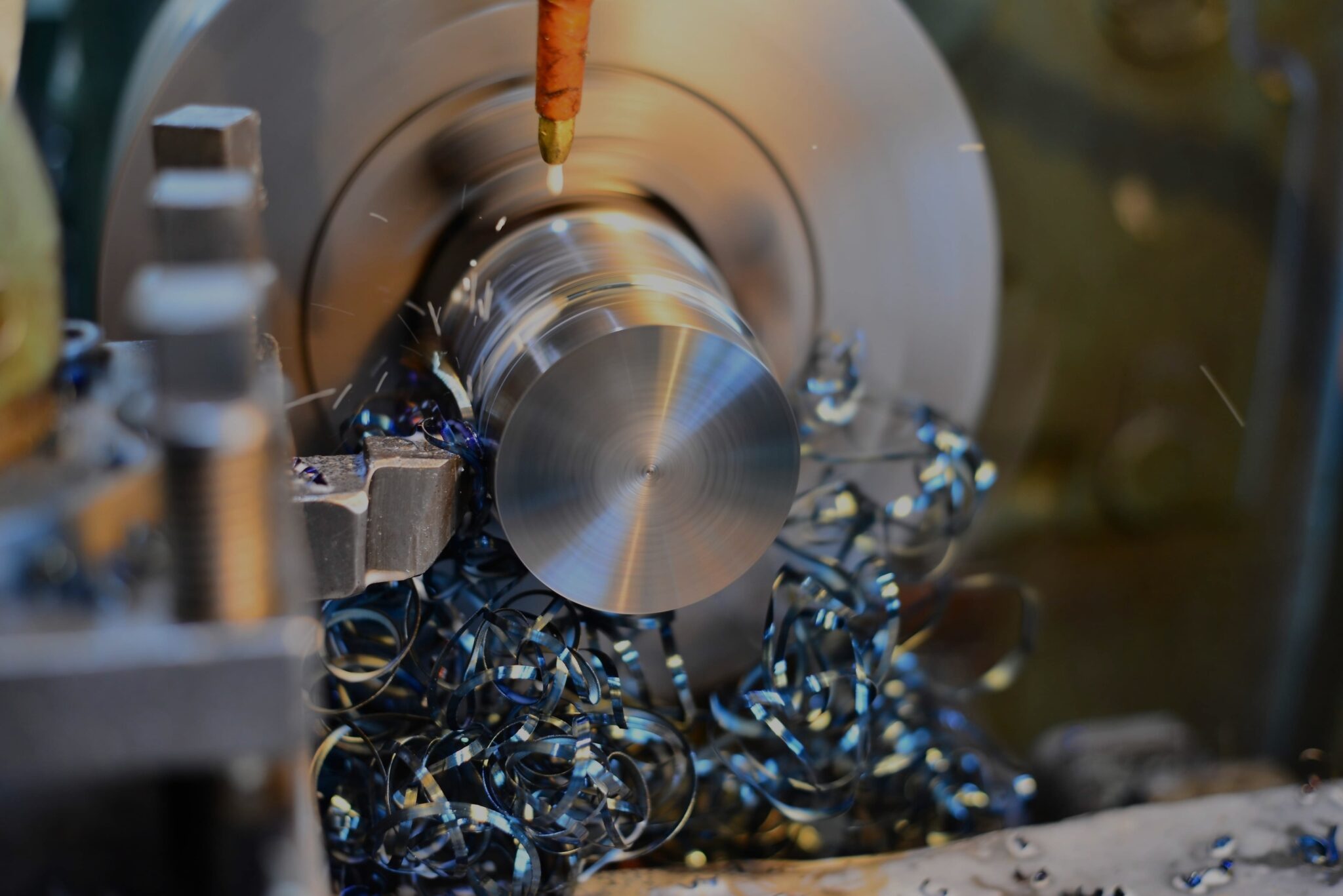

CNC machining is a versatile manufacturing process that allows manufacturers to create medium to high volume runs of highly precise parts from almost any material, from metals and plastics to wood and composite materials.

CNC machining is a subtractive process: it involves the gradual removal of material from a solid block to create the finished part (as opposed to 3D printing, which involves creating a part via gradual deposition of material). Digital design files are used to program the movements of the CNC machine, and the numerical controls direct the manufacturing process. This ensures clean, functional, and repeatable parts every time.

CNC machining is ideal for creating highly accurate parts with tight tolerances, niche parts, and prototypes. CNC-machined parts have the same physical properties as their bulk material, which makes the process ideal for high-performance applications. Common applications include propeller engines in the aerospace industry, surgical equipment in the medical device industry, and electronics enclosures in the semiconductor industry.

CNC machining does have its limitations, particularly when it comes to cost. Initial start-up costs for this process are high, and it costs more to machine parts with complex geometries. Engineers must also consider material costs, especially since material scrap often cannot be repurposed. From a design standpoint, parts with internal geometries or steep undercuts can’t be feasibly machined because the cutting tool must be able to move freely in and out of the block of material. Design teams must carefully evaluate how their part design will be limited if they choose CNC machining.

Die casting, similar to metal injection molding (MIM), is a metal fabrication process that enables manufacturers to create geometrically complex parts with reusable molds, called dies. During die casting, a non-ferrous metal like aluminum is melted down in a furnace and injected into the die at very high pressure.

Die casting is fast and excellent for producing highly accurate and repeatable parts. Die-cast parts are stronger than their plastic counterparts, have smooth surface finishes, and are relatively durable. Additionally, die casting edges out CNC machining when it comes to high-volume production runs and manufacturing products at scale.

The process is the most popular metal fabrication technique in the consumer and commercial industries. Common applications include car parts, children’s toys, parts for sink faucets, gears, and marine applications.

The die casting process is very versatile, but it’s not without its limitations. For example, die casting can create a part of any size and shape, so long as those dimensions are within a casting machine’s capacity limits. Due to this restraint, product teams must design within a limited range of product dimensions. It’s also worth noting that metal alloy malleability can limit the complexity of the final casting.

Volume, cost, and waste considerations should be top-of-mind for product teams looking to settle on a metal fabrication process. CNC machining can be employed for production runs in the hundreds and thousands, but for anything larger, die casting will prove the more economical choice. Creating the die requires upfront time and resource investment, but once it’s created, tens of thousands of identical parts can be manufactured at a relatively low per-part cost.

Die casting may be more cost-effective in terms of volume, but CNC machining offsets the die cost. With CNC machining, engineers can model, machine, test, and remodel prototypes without going back to the drawing board. Making large design changes to dies requires an entirely new mold. When product teams are weighing their options, it’s important to consider how many prototypes may be required before production begins, and to what degree they are likely to deviate from their master pattern.

Product teams concerned with cost-effectiveness or environmental impact should think about waste before making a decision. CNC machining tends to yield a lot of scrap material, but die casting produces less waste because the material is poured directly into the mold. If a team’s carbon footprint or sunken costs are a concern, die casting may be the better choice.

Product teams should consider CNC machining if they require a medium to high production run of precise parts, a degree of design flexibility, and have the capital to invest in CNC machines upfront or outsource production to a trusted partner. On the other hand, product teams should consider die casting if they want a cost-effective way to produce a very large number of identical parts and want to make the most of the money they spend on materials.

Manufacturing process comparisons like these are helpful for gaining clarity and viewing the key differences between two processes from a high level. Still, selecting the process that’s best-suited to a project’s specific requirements can be challenging. A seasoned, global manufacturing partner like Sybridge Technologies can shoulder some of this burden. Our team of designers, engineers, technologists, and advisors have experience with all of the major manufacturing processes — from additive manufacturing to injection molding, urethane casting, and more — and we’re experts at pairing customers’ project requirements with the best-fit solutions. Contact us today. We’ll help you make the right choice.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…