Originally published on fastradius.com on December 9, 2020

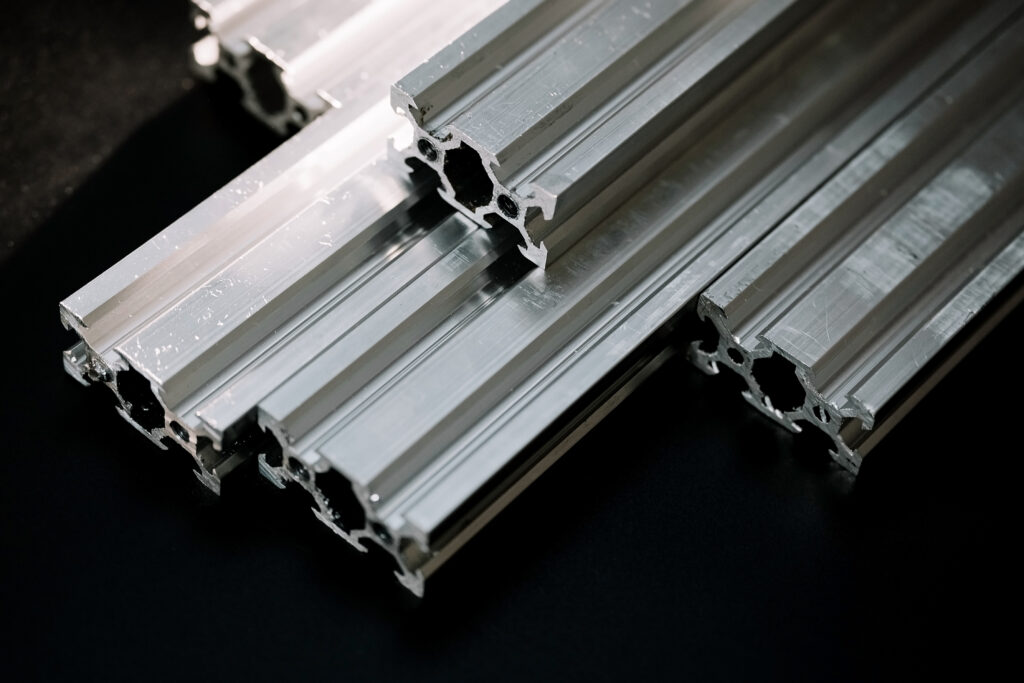

CNC machining is a traditional manufacturing process that uses drills and turning tools to create a part by removing material from a solid block of material. This process is fast, highly repeatable, and ideal for creating parts with tight tolerances. CNC machining can be done with any material that’s rigid enough to machine — from plastic to metal to fiberglass — and aluminum is a popular choice among product teams.

Broadly speaking, aluminum is a strong, non-magnetic, cost-effective material that is highly corrosion-resistant.

6061-T6 is one of the most popular aluminum alloys on the market and most manufacturing companies offer it as the standard grade for CNC machining. It’s versatile, easy to machine, and 6061 can even have different heat treatments.

6061-T6 is an excellent all-purpose material applicable to a wide variety of use-cases. Even though this material has a good strength-to-weight ratio, it’s ill-suited for high-stress applications. Common applications include automotive parts like chassis, bicycle frames, valves, computer parts, and much more.

For high-stress or high-performance applications, engineers should consider 7075-T6. This grade of aluminum is well known for its excellent strength-to-weight ratio and its hardness can even be comparable to that of some softer steels.

Widely used for high-stress applications in the aerospace and military industries, common applications include aircraft fittings, missile parts, and fuse parts. Certain high-performance bikes and sporting goods also include parts made from aluminum 7075-T6.

Despite its high strength and excellent mechanical properties, 7075-T6 does have its drawbacks. This material is less ductile and less resistant to corrosion than other grades. What’s more, aluminum 7075-T6 can be prohibitively expensive for some product teams.

Mechanical specifications:

Aluminum 2024-T4 is a moderate- to high-strength alloy that offers good fatigue resistance and fracture toughness. Aluminum 2024-T4 isn’t as strong as 7075-T6, but it’s still suitable for aerospace applications.

Common applications for aluminum 2024-T4 include aircraft fuselage, transport vehicle parts, and wing tension members. However, product teams should note that this grade of aluminum has poor corrosion resistance and is highly sensitive to thermal shock.

Mechanical specifications:

Aluminum MIC 6 is unique because of its specific combination of alloy and casting method that was developed for producing stable, high-tolerance plates. MIC 6 has impressive stress-relieving properties, excellent accuracy, and high machinability. Aluminum MIC 6 is also contaminant- and porosity-free. This smooth, lightweight option can be found in machining components, electronics, and even laser technology.

One drawback is that MIC 6 threads aren’t as strong as threads made from 6061, and particularly fine threads can lead to early thread failure. Product designers should keep this limitation in mind during the material selection phase.

Mechanical specifications:

Aluminum 6082 has similar properties to aluminum 6061; however, 6082 has a slightly higher tensile strength. Further, this type of aluminum has the highest strength out of all of the 6000 series alloys and it’s exceptionally corrosion-resistant. 6082 is a good option for engineers who want more strength than what 6061 offers, but don’t want to invest in the 7000 series.

Aluminum 6082 is well-suited for general purpose applications that need an added degree of strength and toughness. This material is popular in the construction industry and can be found in many bridges, towers, and trusses. However, product designers should keep in mind that it’s difficult to produce thin walls using aluminum 6082.

Mechanical specifications:

If product teams choose to machine a part using aluminum, they can trust they’re choosing a strong, conductive, and corrosion-resistant material. Aluminum alloys 2024-T4, 7075-T6, and 6082 are best for high-performance applications, while 6061 and MIC 6 can be used in most cases in which an all-purpose aluminum will suffice.

Since CNC machining is so versatile, it can be challenging for engineers to narrow down their list of well-suited materials for a given project. With decades of technical experience, the SyBridge team of expert designers and engineers can help make material selection much easier for every product team. We are committed to helping every customer innovate and achieve their desired results throughout the entire manufacturing process — and with our expert advisory services, teams can rest assured that their material choice will fulfill all critical requirements. Contact us today — let’s make new things possible, together.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…