Previously published on fastradius.com on June 1, 2021

Acrylic, also known as Polymethyl Methacrylate, or PMMA, is a naturally clear, colorless polymer that is widely accepted as an alternative to glass. It is lightweight and durable, boasting resistance to shattering, scratching, weathering, UV light, and environmental wear-and-tear. Acrylic is also biocompatible, making it safe for regular human contact.

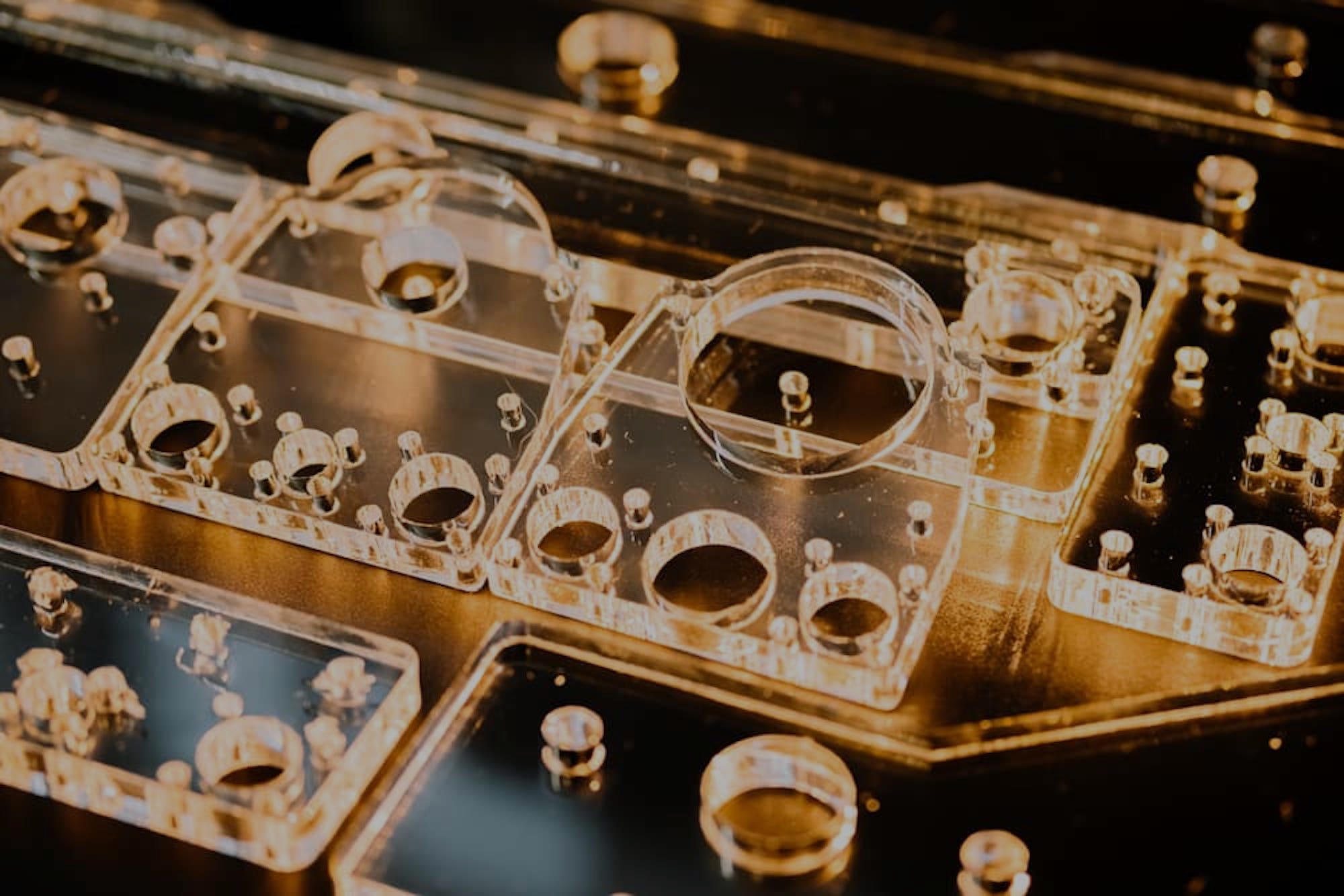

Due to its impact resistance, transparency, and toughness, acrylic is a widely used manufacturing material. Acrylic can create optical devices like contact lenses and glasses as well as window and door panes, greenhouse panels, light fixtures, and even electronic screens. The leading applications of acrylic in the medical industry today are for cuvettes and tubing connectors, but it is also used to produce test kits, syringes, luers, blood filters, and drainage wands as well as flowmeters, blood-pump housings, fluid silos, surgical-blade dispensers, incubators, and surgical trays.

Acrylic can be cut into various complex shapes, but this material requires finesse as it is prone to stress cracking and crazing during machining and post-processing. CNC machining is an excellent way to manufacture acrylic, as it carefully strikes a balance between force and fragility. CNC machined acrylic is strong, durable, and precisely manufactured for ultimate performance. Here’s how it’s done.

Thanks to its precise manufacturing methods, CNC machining can cut acrylic with just the right amount of force to avoid irreversible damage, quickly and effectively producing acrylic components with accurate shapes and sizes. This minimizes waste, increases accuracy, and contributes to better CNC machining dimensional tolerances that improve long-term performance.

Acrylic can be cut using CNC mills or CNC lathes. CNC lathes are generally used for softer materials like wood, foam, plastic, and aluminum, and rotate the part using a stationary tool.

A CNC milling machine is very precise because it uses a multi-point cutting tool that can move along different axes. This presents you with a variety of angles to cut from, which increases precision. CNC milling is perfect for hard materials like metal and some high-performance plastics. Many engineers cut acrylic using a CNC milling machine to achieve optimal handling strength.

Here are five tips for using CNC cutting machines to cut acrylic with precision and minimal damage.

In order to cut acrylic, CNC machine edges must be razor-sharp and strong. This will help prevent acrylic from melting, which negatively affects appearance and functionality. When CNC machining acrylic, stay away from cutters that have been previously used with metal as they will likely have cuts or jagged edges. Smooth, sharp cutter edges can also prevent poor surface finishes.

The material of your cutter is also important. For example, high-speed steel cuts acrylic but doesn’t give a great surface finish. Diamond cutters will give an improved surface finish, but are very expensive. Carbide is often a choice material for CNC cutting acrylic.

For CNC machining acrylic, cutting edge rake angles of 5 degrees and clearance angles of 2 degrees are also recommended.

Ensure your drill bit can effectively create holes in acrylic by choosing the right material. Carbide is a great choice for acrylic drilling, and many manufacturers use O-Flute End Mill Bits that are specifically designed for acrylic cutting and drilling. Also, make sure your bits stay sharp — dull bits don’t create clean edges and can cause stress cracking as well as crazing.

When CNC machining acrylic, it’s best to use a ramp with your bit. To prevent a drill bit from damaging the acrylic, plunge down using a smooth ramp. This will help prevent damage and produce a smooth finish.

When using a CNC machine to cut acrylic, the direction of the tool matters as much as the cutting depth. Make sure you know which way your CNC cutter is rotating or spinning — to the left vs. the right, or counterclockwise vs. clockwise — in order to ensure accuracy in your design features.

It’s important to set the correct feed rate when using a CNC machine. Using a faster feed rate will prevent acrylic from melting. However, if the feed rate is too fast, an acrylic component can break due to extreme cutting pressure. Fast feed rate speeds can also dislodge parts from the workholding or leave blemishes on the part. Similarly, slow feed rates can create inaccurate parts with rough, unfinished surfaces.

The type of acrylic material you choose, as well as part geometry, will determine what feed rate is best for your project.

When you cut acrylic using a CNC mill or a CNC lathe, it’s crucial to choose the right material. Different kinds of acrylic boast unique transparency, rigidity, melting points, and other characteristics. Acrylic’s adaptability opens it up to a wide variety of CNC machining methods and opportunities. An expert manufacturer like SyBridge can help you determine which type of acrylic is best for your specific design and engineering purposes.

CNC machines use cutting-edge technology to create precise, accurate components from acrylic, but the process can be complicated. It takes incredible precision, requiring just enough pressure to form acrylic without breaking it.

At SyBridge, we know just how to sculpt and cut acrylic using the latest CNC machining technology. We can also help you choose the type of acrylic that will give you the best results and recommend CNC machining techniques to optimize your part’s longevity, consistency, and integrity. Contact us today to learn more.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…