Originally published on fastradius.com on April 26, 2021

Computer-aided design (CAD) modeling is the process of using 3D models to test, refine, and reiterate part design plans before physical production starts. In contrast to 3D rendering, CAD modeling is primarily functional and the 3D CAD models you create will often translate into the direct files from which the part is created. Since 3D CAD models are identical to the final product, designers and product teams can use them to optimize their designs down to the smallest detail. 3D CAD models also increase design capabilities and can help streamline the design validation process.

Good 3D CAD models depend on intent — whether it’s for the engineering and manufacturing of a part or a simulation of one — and these three best practices will help you get the most out of your models.

The following CAD optimization tips can be used with any CAD modeling software, including SolidWorks, AutoCAD, and Inventor.

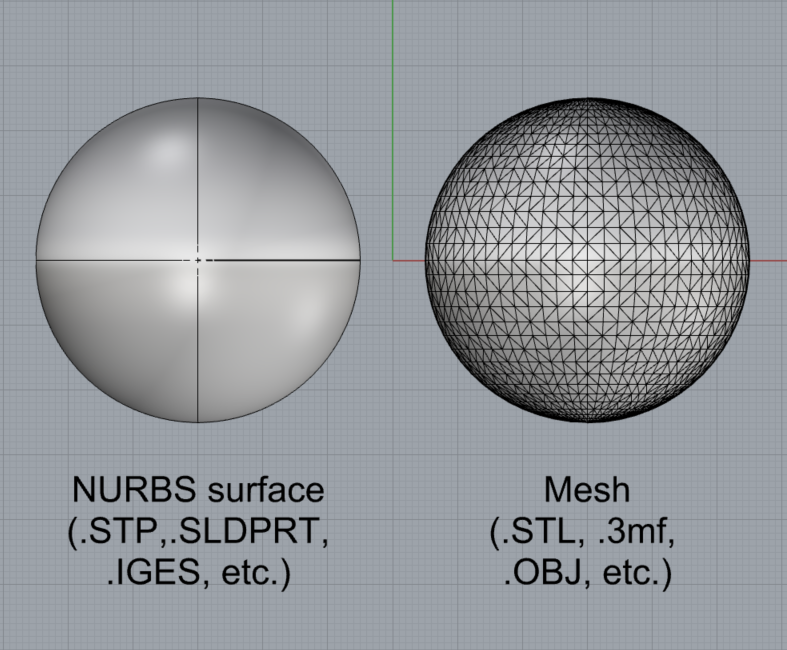

Before you start 3D CAD modeling, make sure you understand what file formats are required for your chosen manufacturing process. For example, CNC machining typically requires STEP or a native CAD program paired with CAM software, while 3D printing is better suited for mesh file formats like STL or .3mf.

Also, don’t forget about baseline computer specifications. Some 3D modeling tasks and file formats require more or less processing power than others, and CAD modeling in general requires a certain amount of computing power. Double-check your CAD modeling software’s requirements to ensure you have enough RAM and computing power to generate high-quality 3D models.

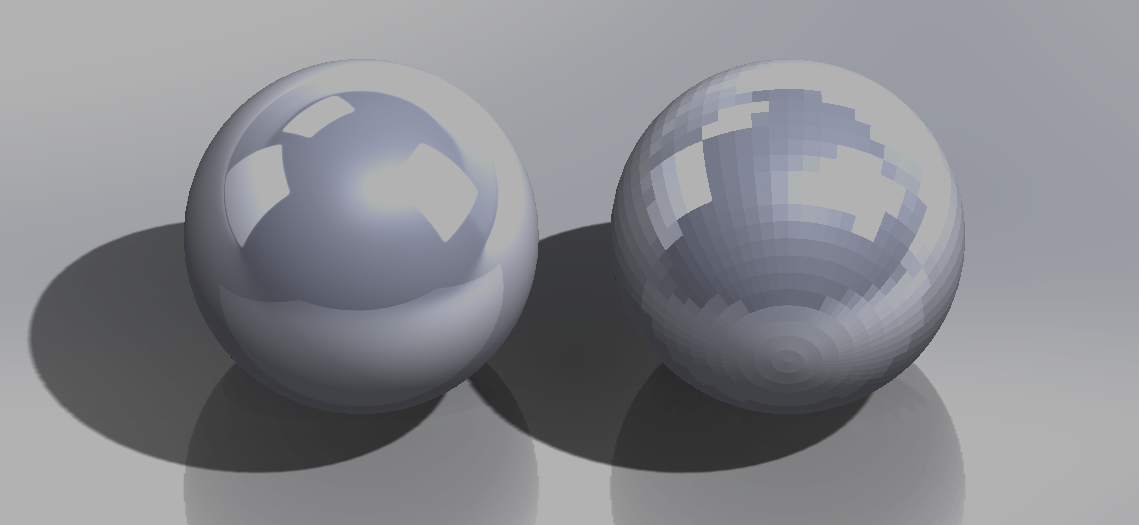

CAD optimization is the time to consider how much and what detail to include in the models for your project . This is particularly important when it comes to using mesh file formats for 3D printing. If the mesh resolution is too low, the 3D printed part will have too many unnecessary facets and deviate from the original design.

To avoid these pain points, it helps to be a little conservative when incorporating detail into your 3D CAD model. Try thinking about the smallest details present in the model and make sure that they are both large enough for the chosen manufacturing process and are adequately captured by the exported file. It is always good practice to review the files after exporting as unexpected issues can arise.

3D CAD modeling is a great way to test out new designs before production begins. However, the ability to re-edit your part design varies depending on the file format you’re using. Also, you have to consider whether or not you’ll need to create a CAD drawing from your 3D CAD model.

Native CAD formats like SolidWorks and Creo are the most editable — going back and making changes is analogous to editing a word document — and you can also create a CAD drawing from this. STL or mesh files, on the other hand, aren’t editable, and trying to make changes is like trying to edit a JPEG. You can’t create a CAD drawing from this format.

To save yourself time — and to avoid having to create an entirely new 3D CAD model each time you need to alter your part design — choose a file format that matches where you are in the design process. Save mesh files for final versions.

3D CAD modeling helps product teams work out any potential design or engineering issues before moving forward in the production process. Still, CAD modeling software can only do so much. By implementing the aforementioned CAD modeling management best practices, you can optimize your 3D models and set your project up for success.

The team at SyBridge has extensive experience with the latest CAD modeling techniques and knows just how to combine them with cutting-edge technologies and traditional manufacturing methods to create something truly incredible. Also, we’re prepared to help with much more than CAD modeling — we can optimize any design, streamline the prototyping and production processes, and fulfill your orders quickly. Contact us today to get started.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…