Originally published on fastradius.com on January 6, 2021

When product teams go through the material selection process, they’re looking for, among other things, a material with mechanical properties that are suitable for the final part’s end-use. This ensures that the material won’t be used in applications beyond its yield strength. Still, even parts made from the right material fail sometimes — why?

One reason materials fail is because of stress concentration, a design flaw that compromises the structural integrity of the part. Here’s everything product teams should know about stress concentration, plus how to reduce it through thoughtful design.

A stress concentration is a point in the part design where stress is significantly higher than in the surrounding area. Stress concentrations are most commonly caused by an abrupt change in the part’s geometry, typically around sharp corners, holes, notches, or grooves.

Stress concentrations are also more likely to occur in parts with complex or sophisticated designs. Even though unique geometric shapes can increase the overall performance of the part, they also cause tortuous load transfers and increase the likelihood of stress concentrations.

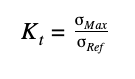

The stress concentration factor, denoted Kt, can be defined as the ratio of highest stress in the part to the reference stress. To express the stress concentration mathematically, the equation is:

σmax equals the maximum stress and σref equals reference stress. A part free from any irregularities has a value near one, while a part with maximum irregularities or discontinuity has a value greater than one.

When a part has stress concentrations, it is more likely to fail in two ways. First, the part tends to fail directly from the stress concentration, which typically results in cracks. Second, even if the part doesn’t get a noticeable fracture, stress concentrations may dramatically shorten the product lifecycle by weakening the part over time.

To ensure the longevity of their parts and prevent fractures, product teams should run FEA models to ensure there are no stress or strain concentrations. Here are four tips all designers and product teams should know:

The most common cause of stress concentrations is an abrupt change in geometry or an abrupt shape transition. To account for this, designers should use specific design measures like fillet radii or tapers to ease the transition from one shape to another. Smoothing out critical areas of the part design influences the flow of stress and prevents stress from accumulating in one location.

Designers can also alleviate stress concentrations by removing material near notches, creating an additional groove called a relief notch. Even though relief notches add a bit of additional geometry to the design, designers can use relief notches to control the lines of stress in a part. These features can be tested and perfected through successive FAE analyses.

For times when holes and notches are unavoidable, it’s best to use many small relief notches. In contrast to the previous technique, where a single groove is used to correct any irregularities, this approach involves surrounding each intentional notch with several smaller notches to smooth out potential stress concentrations. Engineers can remove additional material to create miniature notches while maintaining the original notch.

Sharp corners should be avoided on general principle, especially when CNC machining internal part geometries, but designers should also avoid them if they are worried about creating opportunities for stress concentrations. If the pattern allows for it, designers should always use a fillet radius at sharp corners. This design factor ensures that the cross-section area decreases gradually instead of suddenly, and distributes stress throughout the part more evenly.

Stress concentrations, when too much stress accumulates at one point in the design, can compromise a part’s structural integrity and cause it to weaken or break prematurely. Luckily, product teams can prevent stress concentrations by incorporating the aforementioned design tips and workarounds into their part designs.

A global manufacturing partner like SyBridge can help product teams optimize their designs to reduce stress concentration and take their parts to the next level of functionality and aesthetics. Our team of seasoned designers, engineers, and machinists have access to the latest design technologies available and comes to the table with decades of experience in helping teams perfect their designs for optimal performance. Contact us today — let’s make new things possible.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…