Originally published on fastradius.com on April 21, 2020

“Rapid prototyping” (RP) refers to the quick fabrication of physical products using Computer Aided Design (CAD) during the design phase of the product life cycle. It can be used throughout the design process, from concept creation to final testing. Effective rapid prototyping helps engineers avoid potential pitfalls early on, improves a product’s overall quality, and accelerates speed-to-market. Rapid prototyping can also quickly reproduce complex geometry directly from a CAD file without any need for tooling.

There are two types of prototypes: low fidelity and high fidelity. Low fidelity prototypes are rough mock-ups used in the early stages of the design cycle to help designers and engineers understand the form and function of a concept, allowing them to quickly improve on designs. High fidelity prototypes are nearly exact representations of a final design, used to validate the performance, appearance, and ergonomics of the product.

Rapid prototyping is one of the major benefits of additive, but it’s hard to know which type of 3D printing to use. To ease the pressure of selecting a rapid prototyping process for a given product, we’ve broken down six of the most common methods.

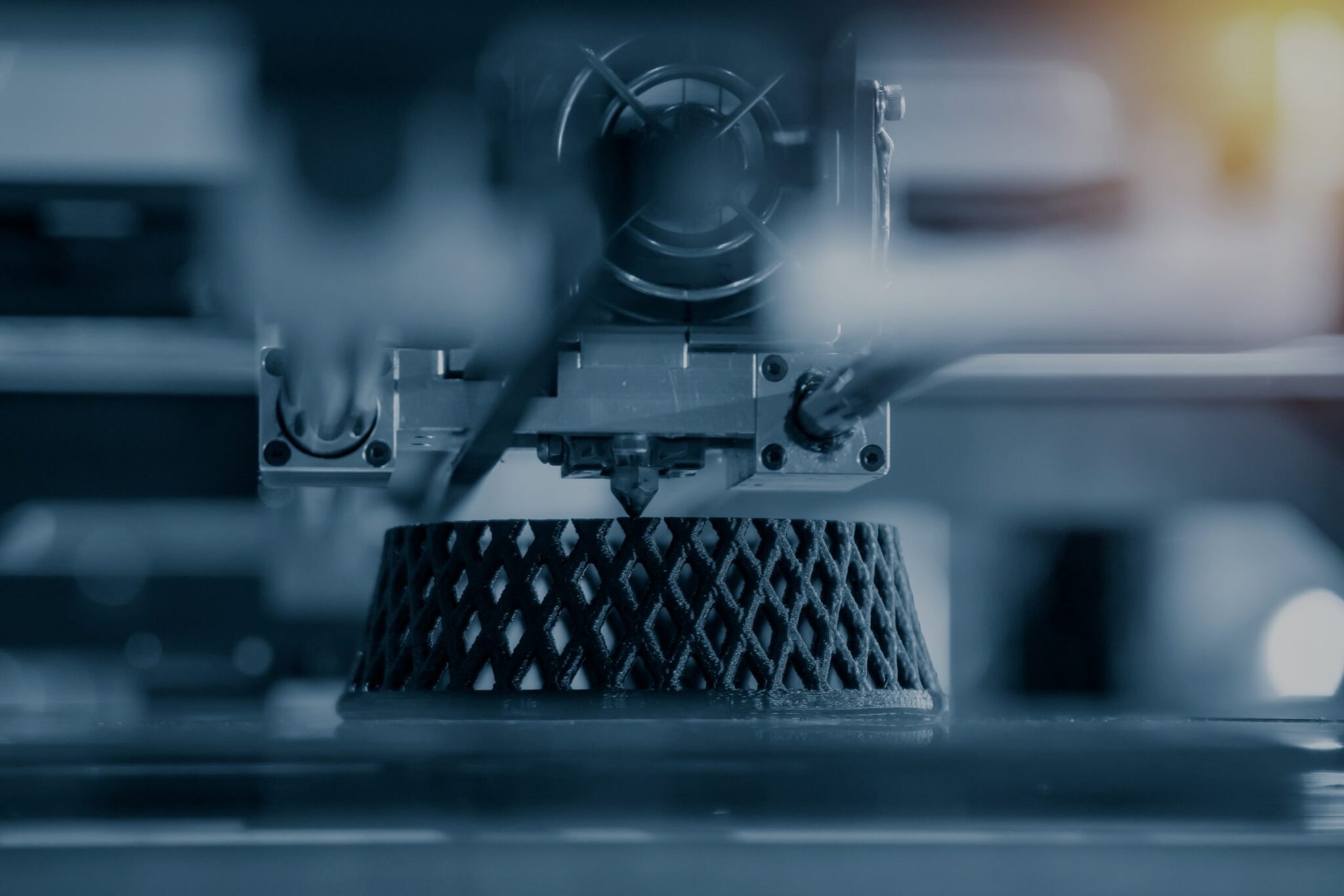

During Fused Deposition Modeling (FDM), a heated printing nozzle melts thermoplastic material such as polycarbonate or ABS inside its barrel and then extrudes the liquified material, layer by layer, along a set toolpath. FDM has been around for many years and is one of the most common prototyping technologies because it’s easy, safe to use, and can produce relatively strong parts at a moderate to low price point.

Unfortunately, FDM isn’t known for its structural integrity. The process often produces parts that are porous, have non-uniform strength, and have limited functional testing ability. FDM is also slower than stereolithography or selective laser sintering. Still, engineers should consider FDM a viable option during the product development stage, as it provides a cost-effective means for rapid prototyping.

Stereolithography (SLA) is the tried-and-true rapid prototyping choice for many design and engineering teams. During this process, a computer-controlled UV light laser traces each 2D slice of a part on the build platform, curing a liquid photopolymer resin. Each completed layer adheres to the next and the process is repeated until a full part is formed. It’s fast, affordable, and widely available. SLA prototypes are commonly used for medical devices and models.

Since SLA doesn’t require engineering-grade resins, prototypes made by this process tend to be weaker and unfit for strenuous testing. What’s more, UV can degrade over time and when exposed to humidity. However, SLA parts have a much better surface finish than FDM due to the higher resolution of the laser and the reduced appearance of layer lines. Engineers should consider prototyping with SLA for limited-use parts with intricate designs or higher surface requirements.

Carbon’s Digital Light Synthesis (DLS) uses a photochemical process to build parts. Light is projected through an oxygen-permeable window and down into a vat of UV-curable resin. Then, a digital device projects a sequence of UV images into the resin, the part solidifies layer by layer, and the full part is formed. The printed part is baked in a forced convection oven and the application of heat gives DLS printed parts their exceptional mechanical properties.

This process is ideal for developing high-fidelity prototypes and small, isotropic parts because the printing process is continuous. DLS printed parts are similar in strength and mechanical properties to parts produced using injection molding. DLS is also compatible with a wide variety of industrial-grade materials, making it ideal for multiple part iterations.

However, DLS is not the best prototyping process for printing parts larger than the palm of one’s hand and engineers might have to rethink their designs to account for this process’s supports. Also, it’s typically more expensive than other prototyping processes available and doesn’t have a large build volume.

Selective Laser Sintering (SLS) uses a powerful computer-controlled laser to sinter multiple layers of powdered material, typically nylon-based, into a solid. In addition to nylon, SLS is compatible with elastomeric TPU powders that are mechanically similar to thermoplastics. This rapid prototyping process is particularly well-suited for creating automobile hardware parts.

Prototypes built with SLS are tougher, more durable, and more suitable for functional testing than those built with SLA. This process is also more versatile than SLA, since it can be done using a wide variety of materials while still maintaining uniform strength. However, SLS-printed products are porous, less detailed, more expensive, and take longer to produce.

Multi Jet Fusion (HP MJF) is a powder bed technology that builds up 2D cross-sections using inkjet heads to deposit a fusing agent on a layer of powder that is then fused by an infrared lamp. The parts are then excavated from the build box and blasted to remove the excess powder.

HP MJF is fast, about three days faster on average than SLS. This process can produce functional, chemically resistant, and highly dense prototypes in as little as a day. This makes it ideal for watertight applications, enclosures, and other prototypes that have complex assemblies. Prototypes can also be made in full color, allowing designers to test the aesthetics of a product as well. However, HP MJF can only be used with PA12 nylon and it does not promise high accuracy when it comes to creating small features.

During the PolyJet printing process, a print head sprays a layer of photopolymer resin onto a gel matrix, and proceeds to cure the resin under ultraviolet light. This produces ultra-thin and incredibly smooth layers of material that can give your prototype a superior surface finish. Additionally, the print head can eject droplets of different materials, allowing you to create multi-material prototypes in a single print.

However, PolyJet shares many of SLA’s vulnerabilities. Prototypes built with this process aren’t very strong and can degrade due to UV sensitivity. Still, if engineers are looking for a rapid prototyping process that’s compatible with many materials and produces an elegant, high-resolution print, PolyJet can be a suitable option.

Choosing the best rapid prototyping process can feel overwhelming. By balancing budgetary constraints, timeline, physical requirements, and other critical factors, engineers can begin zeroing in on the rapid prototyping process that’s best for their project. Partnering with an expert manufacturing partner can help ensure you’re making the right choice.

If you’re looking for the right partner to optimize not only your rapid prototyping process, but every phase of your manufacturing project, turn to SyBridge. Our team of experts bring years of experience to the table and can elevate your operations from concept to delivery, guaranteeing that you wind up with a product of unmatched quality. Contact us today to get a quote.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…