Originally published on fastradius.com on June 5, 2020

The term photopolymer refers to a class of light-sensitive resins that solidify when exposed to ultraviolet (UV) light. When the liquid photopolymer resin comes into contact with a UV light source — typically a lamp, laser, or projector — photoinitiators transform that light energy into chemical energy. Then, oligomers or “binders” and monomers combine, harden, and form bonds that create the polymer structure. Photopolymers are either thermoplastics, which melt at high temperature, thermosets, meaning they can’t be melted or reshaped once cured by heat.

Photopolymers represent the largest portion of the additive manufacturing materials market and have a wide variety of applications. Today, photopolymers are common candidates for parts used in the dental industry and are frequently used in teeth bonding or protective coatings. Adhesives made with photopolymer resin are also widely used to make catheters, medical filters, surgical masks, and even specialty electronics.

Here’s a crash course on this popular material and how it’s used, plus key considerations for engineers.

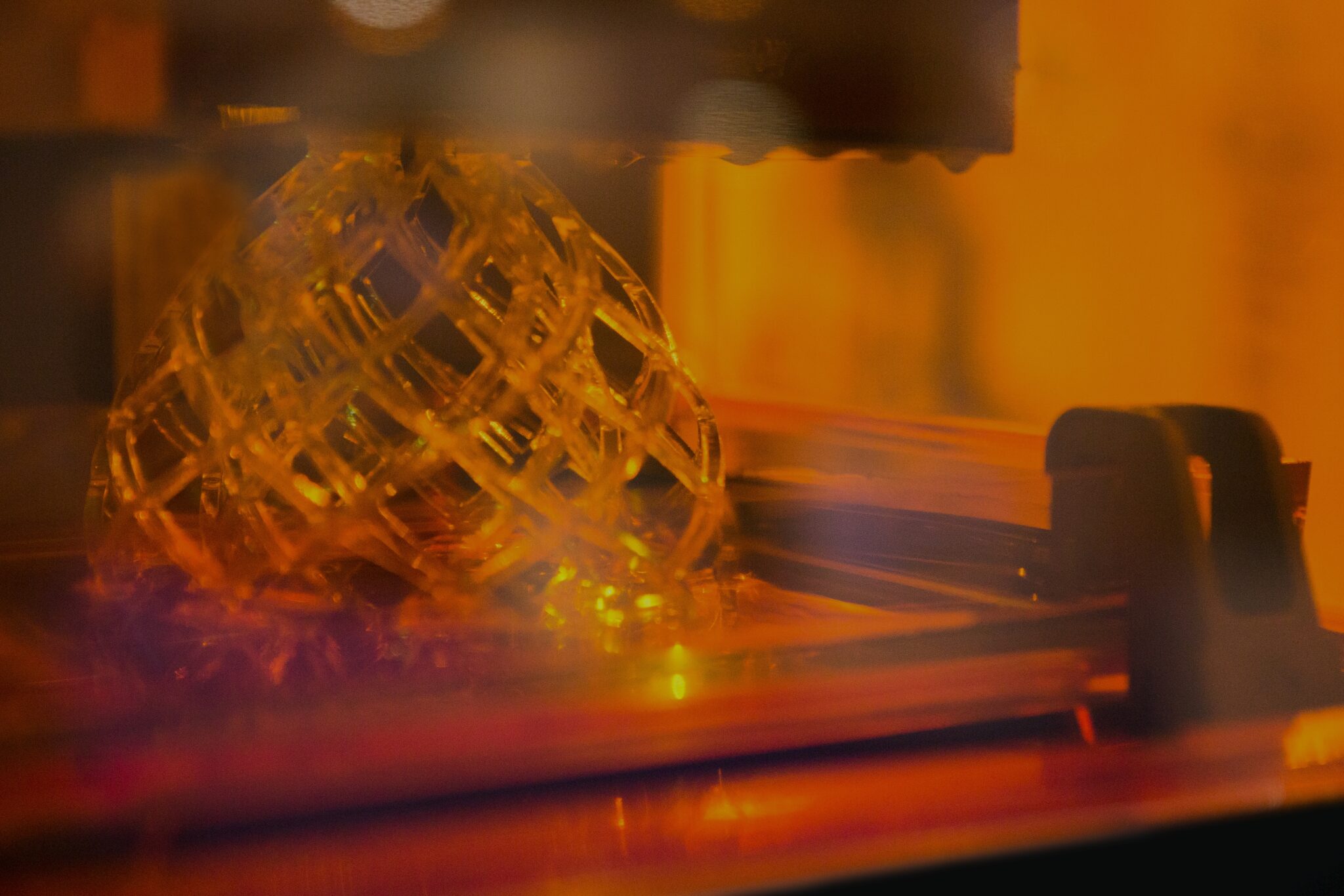

Photopolymers are compatible with a number of additive manufacturing processes. In all of these processes, a resin is cured with light, then a full part or prototype is built up layer by layer until completion. The most popular photopolymer 3D printing processes include the following:

Stereolithography (SLA) is the original photopolymer 3D printing process. During printing, a laser shoots highly-concentrated beams of ultraviolet light (like a laser) onto the surface of a vat of photopolymer resin.

The laser solidifies individual layers of resin on a platform until the final part is completed. In the case of inverted SLA, the projector is placed on the bottom and the platform moves up until printing is completed. Parts made with the process boast exceptional surface finish, but aren’t typically as strong as parts made with other processes, such as fused deposition modeling (FDM).

Carbon® Digital Light Synthesis (DLS)™, formerly known as Continuous Liquid Interface Production (CLIP), uses a digital projector to build parts. This photochemical process projects UV light through a UV-transparent oxygen-permeable window at the bottom of the vat. The sequence of UV images are projected through the window and into the photopolymer resin, causing the part to solidify and the build platform to rise.

DLS is a continuous and quick printing process due to some of these process improvements. However, most materials available through DLS are a two-part cure, meaning they require a thermal bake after printing to achieve their final form and properties. This second step of baking allows the printing process to be faster and produce higher grade material properties with exceptional stiffness and strength. Engineers turn to DLS when they want to create small, isotropic parts with excellent mechanical properties.

PolyJet doesn’t use a vat of liquid photopolymer resin to build parts, setting it apart from SLA and DLS. Instead, a layer of the resin is sprayed onto a gel matrix and then dissolved once the manufacturing process is complete.

Parts made with this process aren’t known for their strength and are highly sensitive to UV rays. Fortunately, what PolyJet parts lack in strength they make up for in resolution. PolyJet is the 3D printing process of choice for manufacturing aesthetically pleasing parts with unmatched surface finishes.

Photopolymers have applications in a wide variety of industries, but these applications are generally highly specialized. Photopolymer resins aren’t particularly strong or durable when compared to similar high-strength injection molding materials, and they’re susceptible to creep after carrying heavy loads for a long period of time. However engineers can build small, high-resolution prototypes with even surfaces and complex geometries using this resin. For each application, engineers need to understand their specific requirements of their application and whether the available materials are suitable.

Limitations notwithstanding, the future of photopolymers looks bright. Various kinds of photopolymers already exhibit unique chemical and mechanical properties that are ideal for a range of specific use cases. And as technology advances, photopolymers are bound to evolve, enabling manufacturers and product teams to capitalize on the benefits of the material without sacrificing on durability or surface finish quality.

When you partner with SyBridge, you have a dedicated team of manufacturing experts at your disposal. Regardless of where you are in the design and development process, our team of seasoned engineers and designers can simplify the production process, whether that means design optimization, advising on materials and finishes, or combining 3D printing processes with traditional ones. At SyBridge, we’re committed to helping every client innovate more quickly and effectively. We’re here for you — contact us today.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…