Originally published on fastradius.com on March 30, 2022

The additive manufacturing industry is older than many people think. In fact, roughly the past 40 years are peppered with significant advances in 3D printing. Engineers started using stereolithography (SLA) technology for manufacturing prototypes in the 1980s and use of fused deposition modeling (FDM) quickly followed in the early 1990s. Fast forward to 2016, Multi Jet Fusion (MJF) hit the market and transformed the additive manufacturing industry yet again.

FDM is one of the oldest 3D printing technologies, and MJF is among the youngest, but both can quickly produce accurate parts. Which is best for your next project? Here’s what you need to consider before you make a final decision.

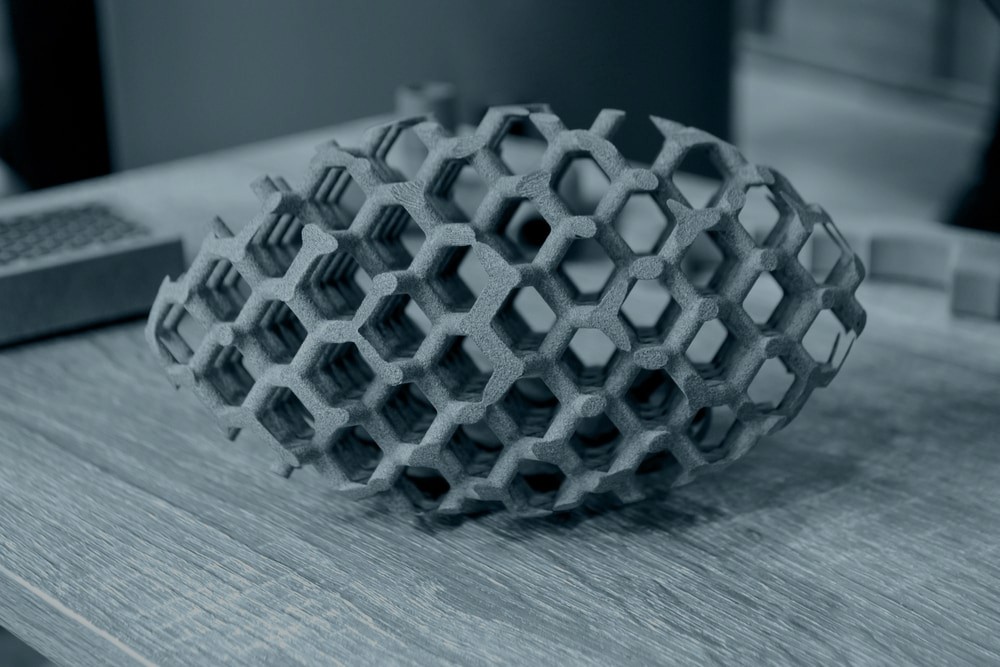

HP’s expertise in inkjet printing technology and precision mechanics informed the company’s 2016 foray into the 3D printing sector. MJF technology builds parts up layer by layer in a bed of powder material to create strong and accurate components with fine details, consistent mechanical properties, and quality surface finishes.

Capable of producing 100% filled, functional, and detailed parts that don’t require support structures, MJF is suitable for creating robust prototypes or low-volume production runs. Popular applications include jigs, fixtures, electronic housings and mechanical assemblies.

At the beginning of the Multi Jet Fusion 3D printing process, your engineer will place the moveable build unit in the printer, and the printer will deposit a layer of powder material, such as polyamide 11 (PA 11), polyamide 12 (PA 12), or TPA. Then, the printing and fusing carriage will move across the build area, and the inkjet nozzles will apply fusing agents. Once the layer is complete, the build unit will retract, the machine will deposit another layer of powder, and the process will repeat. Once the print is complete, the operator will then remove the build box, cool and separate the part from loose powder, and use a bead, air, or water blaster to remove any leftover powder.

MJF is up to 10 times faster than other 3D printing technologies, making it well-suited for rapid prototyping and mid-sized batches of end-use parts. Support structures aren’t required, which means you can save on materials and reduce production time. Plus, since MJF printers can print ultra-thin layers, you can produce dense parts with low porosity, high resolution, good mechanical properties, and consistent strength in all directions.

However, the technology is more expensive than some other additive manufacturing technologies, and it’s only compatible with a few materials.

FDM is cost-effective and offers a range of printer sizes. It is ideal for printing during the initial concept development and mid-fidelity prototyping phases to gain a general idea of how your final part will look, feel, and fit with other components. FDM can also be used for end-use products.

Creating a part using FDM requires a printer, a digital model, and a spool of filament. Acrylonitrile butadiene styrene (ABS), acrylonitrile styrene acrylate (ASA), polycarbonate (PC), and nylon (PA) are among the most popular filament materials.

After slicing your digital 3D model, your printer will melt and extrude the plastic filament from a nozzle as it moves along the X, Y, and Z axes. The build platform will move down (or the extrusion head will move up) after each layer, and the process will begin again. Most layers are 0.1 mm to 0.5 mm tall, but you may need to use smaller layer sizes if you need smoother surfaces, a curved print, or a high level of detail.

FDM has lots to offer, from fast turnaround times to compatibility with a wide range of materials and colors. When using an FDM printer, you can use ABS, nylon, and more to create strong and functional prototypes or end-use parts. Industrial FDM machines have build sizes as large as 1,000 mm x 1,000 mm x 1,000 mm, and you can just as easily print a custom part as you would a mass-produced part.

FDM also has a few drawbacks. For one, it doesn’t offer the same quality, reliability, or dimensional accuracy that other 3D printing technologies do. Nozzles can clog up, or print beds can become miscalibrated, causing failed prints. Like with MJF, if your part cools at different rates, you may notice warping. You might also see visible layer lines and lower resolutions.

Additionally, FDM parts are anisotropic and often require support, so you’ll need to consider orientation and support structure placement while designing your part. You may also need to post-process your parts via sanding, polishing, acetone vapor smoothing, or epoxy coating or choose a more expensive dissolvable support material.

When comparing FDM vs. MJF, each process has pros and cons, and there are certain situations where it makes sense to use one over the other. You need to consider:

MJF and FDM both offer relatively short turnaround times and quality parts. When deciding between the two, you need to consider production requirements, environmental goals, and the desired part quality, complexity, material, and properties.

If you’re unsure whether you should use MJF or FDM, SyBridge’s experts can help you choose the technology that best suits your project. We can also optimize your design and produce your parts using industrial-grade printers and materials. Contact us today to get started.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…