Previously published on fastradius.com on September 18, 2020

Stereolithography (SLA) is a 3D printing process that uses photopolymerization to build parts with high-quality surface finishes, excellent resolution, and intricate designs. SLA typically isn’t suitable for high-performance applications, but engineers can strengthen parts and effectively utilize mechanical properties by choosing the correct resin.

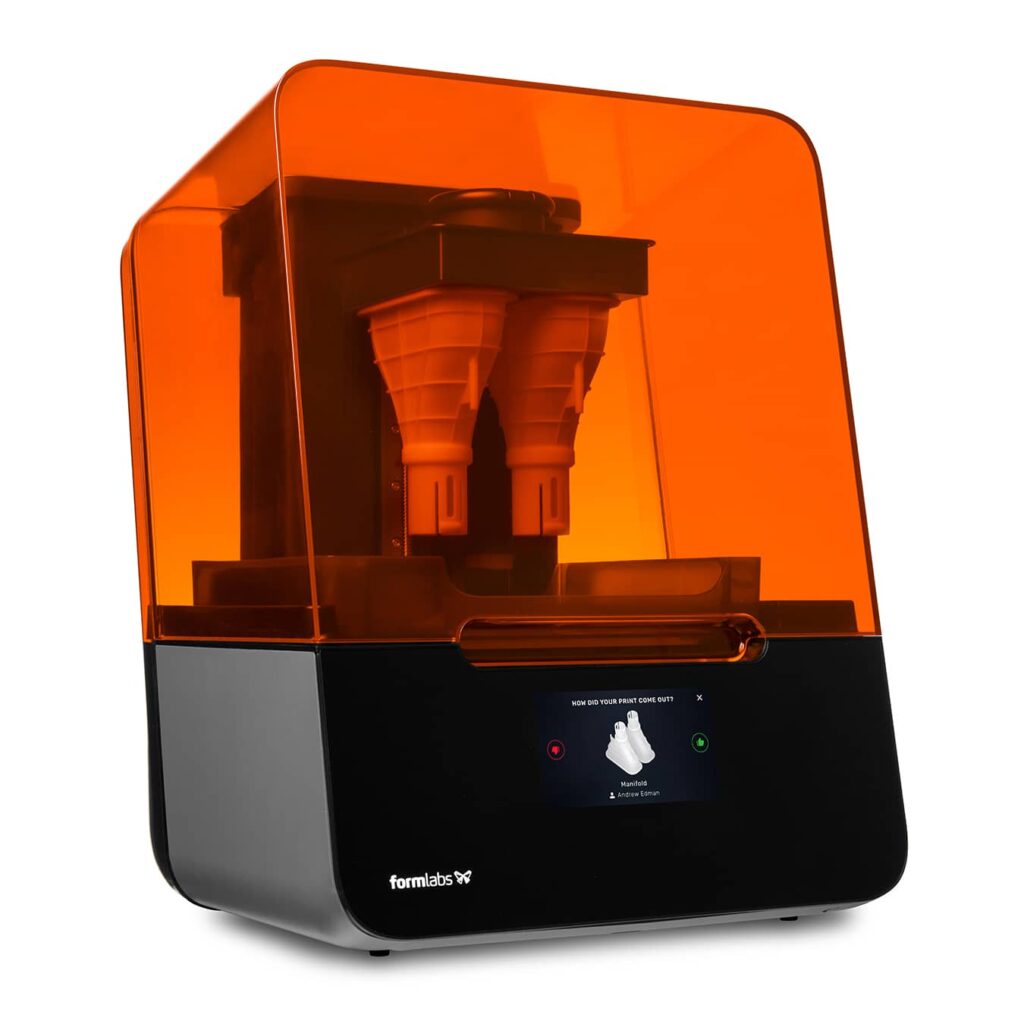

Rigid Resin 1 L, created by Formlabs, is a type of engineering resin specially formulated to withstand extensive testing and perform well under repeated stress. Here’s everything you need to know about Rigid Resin, plus key manufacturing considerations for engineers.

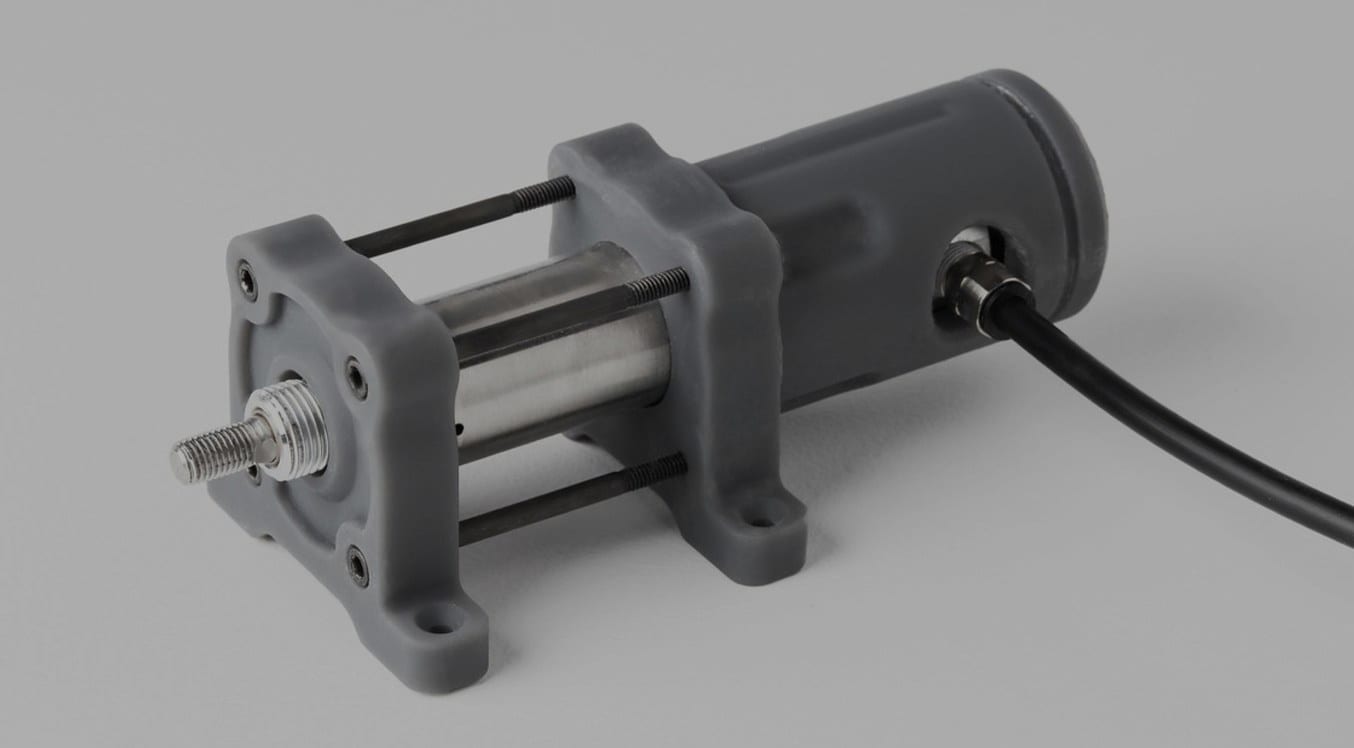

This material is reinforced with glass powder to improve its strength and offer a polished finish after curing. It’s strong, stable, and highly resistant to deformation over time. Rigid Resin is ideal for creating jigs and fixtures, parts with thin walls and features, and manifolds.

Some key mechanical specifications for Formlabs’ Rigid Resin 1 L, post-cured, are as follows:

Since Rigid Resin is so stiff and tends to be brittle, it’s not recommended for parts that must bend or parts to be used in drop or impact testing.

Rigid Resin follows the same basic manufacturing requirements and procedures as many other resins, but with two notable exceptions.

Standard resin tanks are incompatible with this material because the elastic layer in the tank will swell if it’s exposed to the uncured resin, so engineers and manufacturers must use Formlabs’ Resin Tank LT for Form 2, or the Form 3 Resin Tank V2 for Form 3. Most importantly, Rigid Resin must be cured to achieve the highest possible strength and stability. Formlabs recommends curing Rigid Resin for 15 minutes at 81°C for a 116% increase in tensile modulus.

In terms of finishing, engineers should wash Rigid Resin in isopropyl alcohol for 15 minutes, and allow it to dry before post-curing. There will be white glass particles left behind in the isopropyl alcohol after washing the printed parts, so be sure to use a separate wash bucket to keep the glass particles from transferring to parts printed with other types of resins.

Engineers should consider using Formlabs’ Rigid Resin 1 L when they need a material that’s exceptionally stiff, strong, and capable of producing high-quality parts with delicate features.

Rigid resin is comparable to other glass-filled thermoplastics and outpaces standard resins as well as Formlabs’ Flexible Resin 1 L when it comes to strength and stiffness. Rigid Resin also offers exceptional print quality at around 50 to 100 microns.

Common applications for Rigid Resin include functional prototypes, end-use production parts, turbines and fan blades, automotive housings, and electrical enclosures. Its strength and durability also make it ideal for fan blades, turbines, as well as various jigs, fixtures, and tools.

There are numerous other factors engineers must consider — cost, function, ease of manufacturability, and other project-specific requirements — before settling on the best-suited material for their parts. Luckily, material selection becomes much easier with the help of a trusted manufacturing partner.

SyBridge is a one-stop-shop for on-demand, additive, and traditional manufacturing innovation. Our highly qualified engineers and designers have years of experience seeing projects through — from ideation and design optimization to prototyping and fulfillment. We’ve learned a lot about a wide variety of materials along the way. We’ll help customers zero in on their functional, aesthetic, time, and cost requirements to help them determine the perfect plastic or metal material for their given part. Contact us today to get started.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…