Previously published on fastradius.com on October 14, 2019

Epoxy 82 (EPX 82) is an additive material developed by Carbon® for its digital light synthesis (DLS) process. By blending functional toughness, stiffness, and temperature resistance, this high-strength engineering material is ideal for automotive, industrial, and consumer applications. Comparable to glass-filled Polybutylene Terephthalate (PBT), EPX 82 has a wide range of applications and can replace legacy injection molded and plastic CNC components.

Due to its toughness and heat deflection properties, EPX 82 can be described as one of Carbon’s most accurate high strength and rigid materials. Here we have broken down some of EPX 82’s key mechanical specifications:

Read the Carbon EPX 82 technical data sheet for more information.

Described as a two-part epoxy resin, EPX 82 has good chemical, thermal, and UV stability – making it a diverse and versatile material for a wide array of applications. More specifically, this material has been specially formulated for automotive and industrial production. Its impact and heat resistance also allows for temperature cycling durability making it suitable for continuous use between varying temperatures. Its high resolution also allows for precise and accurate designs.

EPX 82 meets USCAR-2 fluid compatibility standards, meaning it is compatible with a wide range of fluids including power steering fluid, diesel, auto transmission fluid, diesel exhaust fluid, engine coolant, E85, gasoline, and engine oil— perfect for any automotive application. It is also important to note that EPX 82 is certified for UL94 HB.

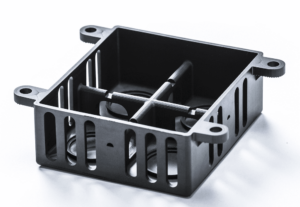

Comparable to lightly glassified injection mold materials, you may find EPX 82 replacing applications using GF PBT or GF Nylon and plastic CNC components. Today, EPX 82 is used for applications such as housings, covers, clips, badges, light fixtures, jigs, and more.

Its excellent rigidity, durability, and temperature resistance make it an attractive material for automotive, industrial, and other demanding industries requiring high-quality engineering materials.

SyBridge strives to help you find the best material for your part. From application to discovery, we bring the future of manufacturing and supply chains to our clients. Contact our team today to learn more about EPX 82, discuss lead times, or share any other considerations you may have for your next application.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…