Originally published on fastradius.com on September 24, 2020

If you’re looking to 3D print parts that mimic the properties of silicone, consider Elastic Resin from Formlabs, which is designed to offer high elongation and energy return, mimicking the look and behavior of silicone.

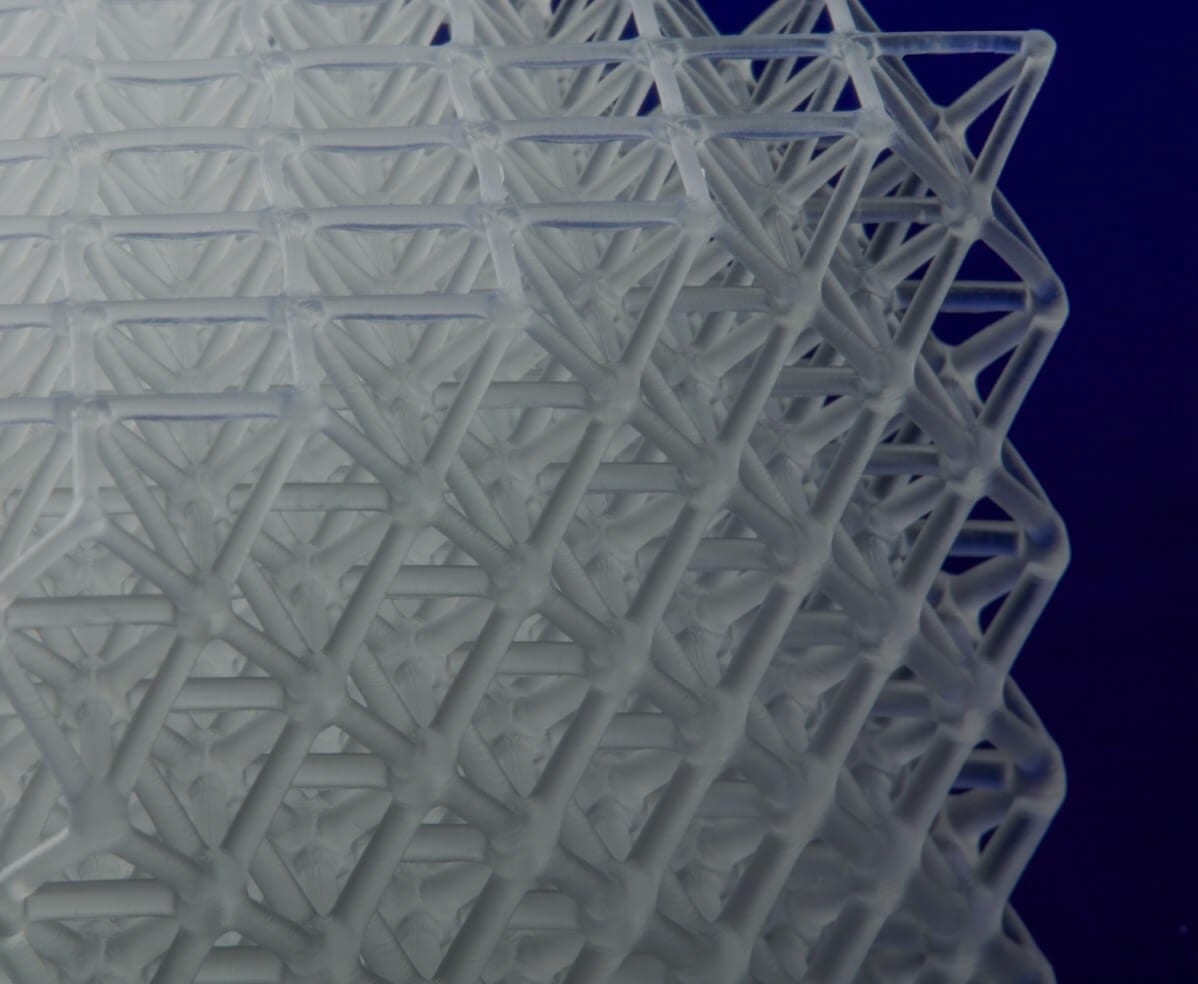

Soft resins of this type are often used to produce parts via stereolithography (SLA), a method of 3D printing that involves laying material in thin layers to form a three-dimensional part.

Elastic Resin, or Elastic 50A Resin, is an elastomeric material that offers low durometer, high elongation, and high energy return. This means that it will bend, stretch, and compress well. In addition, it’s highly resistant to tearing, and it’s shatter-proof. When stretched or bent, it quickly bounces back to its original shape.

Unlike many other resins, Elastic Resin is transparent. It’s also one of the softest resins available on the market today, while still retaining an exceptionally high tear strength. However, for parts that require flexibility and elasticity, or whose properties should mimic those of silicone, it’s highly suitable.

Some key mechanical specifications for Formlabs’ Elastic Resin, post-cured, are as follows:

Elastic Resin is ideal for applications in which silicone would be suitable, and is a convincing silicone imitation. It’s a particularly good fit for soft-touch parts that must also be durable, flexible, and shatterproof.

Because of its silicone-like properties, Elastic Resin is ideal for prototyping parts that will be made with silicone using methods like transfer molding or injection molding. These time- and labor-intensive techniques can even be employed to produce low-volume runs of prototypes in silicone. Using Elastic Resin, product teams can create functional prototypes with much less time and labor, perfecting the design before making the final part in silicone.

Among the most popular applications of Elastic Resin are medical models and prototypes for silicone parts. Because Elastic Resin is transparent and can be manufactured quickly and in small quantities, it’s ideal for creating patient-specific anatomical models to help surgeons and other medical professionals prepare for complex cases. It’s also suitable for creating medical models for educational purposes.

Elastic Resin is also useful for prototyping products that will later be made out of silicone, including wearables and consumer goods. It’s also recommended for compliant features for robotics and for special effects props and models.

Elastic Resin is a unique, versatile material that can be used in a wide range of applications to imitate silicone. However, like Flexible Resin, it should not be used for parts with fine details or parts requiring a rigid structure or shape. Because it is so soft, Elastic Resin requires even more support than Flexible Resin, which needs to be taken into account during the design phase.

Elastic 50A Resin should be washed for no more than 10 minutes on the build platform. This initial wash makes it easier to remove. Once it’s removed, it should be washed for 10 more minutes using fresh solvent. More than 20 minutes of wash time may cause the material to absorb solvent.

Elastic Resin is ill-suited for parts that require a high degree of detail or that must hold a rigid structure or shape. Additionally, it’s important to note that Elastic Resin requires more support than Flexible Resin or other resins. Isolated supports more than 20 mm long may lead to print failures, and isn’t recommended. For that reason, it’s a good idea to try and design self-supporting structures when working with Elastic Resin.

It’s essential that teams working with Elastic Resins are aware of its specifications and limitations. Partnering with an on-demand digital manufacturer like SyBridge can help product teams of all shapes and sizes evaluate appropriate materials for a given part and optimize the part’s design in accordance with the mechanical specifications of a chosen material. SyBridge offers both traditional and additive manufacturing services, and our experience working with a wide range of materials — including traditional resins and Elastic Resin — makes us a valuable partner for any product team.

From design and material selection to prototyping and fulfillment, SyBridge supports its customers through every step of the manufacturing process. Contact us today to learn more about how we can help your team use Elastic Resin.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…