Previously published on fastradius.com on April 15, 2020

Manufacturing leaders are wrestling with the urgency of the current emergency situation. We’re experiencing a volatility in supply and demand that none of us have seen in our lifetimes, and the COVID-19 pandemic will continue to affect our societies and economies acutely for months, with residual effects spanning years, if not decades.

While there is no historical precedent to guide us, manufacturers have two clear obligations: First, we need to pivot quickly to manufacture the life saving medical equipment that will treat the sick and keep our populations safe. Second, we need to keep our businesses running for our customers, employees, shareholders, and the health of the economy as a whole.

Clear solutions are hard to come by these days, but here’s some good news. Digital manufacturing, especially industrial-grade 3D printing, provides benefits companies can use right now to mitigate business risk while meeting new and existing demand. Here are three of those benefits.

Many businesses are seeing interest in their core products wane, and with less revenue coming in, the costs of capital, MOQs, and warehousing become harder to justify. On-demand additive manufacturing is perfectly suited to meet volatile demand because it allows companies to meet low demand exactly, virtually eliminating carrying costs.

On the other hand, the demand for PPE and medical devices has grown faster than our existing supply chains can handle. Without the massive investment needed to tool up a traditional production line, additive manufacturing can help businesses quickly pivot to producing new products on-demand in volumes that supplement the existing supply chain. Making PPE and medical equipment additively mitigates the risk of standing up a factory to meet a short-term surge in demand.

Additive manufacturing simplifies product development and supply chain management, allowing companies to produce goods on-demand and get life-saving supplies to market quickly. A 3D printed part can be prototyped and tested in a matter of days–or sometimes hours–rather than the weeks or months it would take to design and test tooling for a traditional process like injection molding.

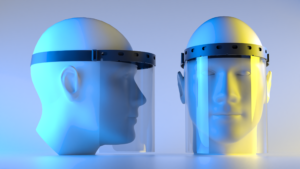

Here at SyBridge, we responded to the dire need for PPE by developing a 3D printed face shield. In only seven days, we developed a production-ready product that can be printed on multiple additive technologies. We’ve shipped thousands of these shields to medical professionals and other first responders, and the process only took a few days from inception to fulfillment.

Digital manufacturing technology allows us to move extremely quickly to fulfill variable demand. At SyBridge, we built software that gives our customers visibility into the entire production process from the first design iteration through order shipment, and we’re now using that technology to manage the production and fulfillment for our critical PPE initiatives.

This digital connection allows us to collaborate on design, troubleshoot on the factory floor, and ship parts — all from distributed locations around the world. Plus, the data needed to make parts can be accessed from the cloud, so parts can be made repeatedly and reliably wherever the required digital manufacturing technology exists.

This allows us to bring production closer to end-users, cutting down transit time and circumventing issues with shipping across borders. Taking it a step further, production nodes can be co-located with distribution hubs to save valuable time over traditional warehousing and fulfillment processes.

Supply chain disruption didn’t start with COVID-19, and it won’t stop when the threat of the virus recedes. This pandemic will end, and we’ll need to sort out a new normal that can handle the persistent issues facing our global economy: tariffs, political upheaval, natural disasters.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…