Originally published on fastradius.com on May 1, 2020

3D printing has received a lot of buzz over the past decade, but it’s hardly a new invention. Hideo Kadama pioneered what’s now known as additive manufacturing in 1981 when he described a rapid prototyping system that could build models using multiple layers of solidified photopolymers. Since then, engineers haven’t stopped innovating with 3D printing. The industry even gave rise to an array of medical applications, producing 3D printed bladders, kidneys, prosthetic legs, and blood vessels, all between 1999 and 2010 alone.

Arguably the most important era in 3D printing’s history is the mid-2000s, when additive manufacturing became increasingly democratized. In 2009, the old patents on fused filament fabrication (FFF) expired and desktop printers flooded the market. Now, amateurs and established engineers alike can create CAD designs and build just about whatever they want, from bolts to toys to firearms. However, there’s a big difference between industrial-grade fused deposition modeling (FDM), the Stratasys branded name for FFF, and at-home filament extrusion.

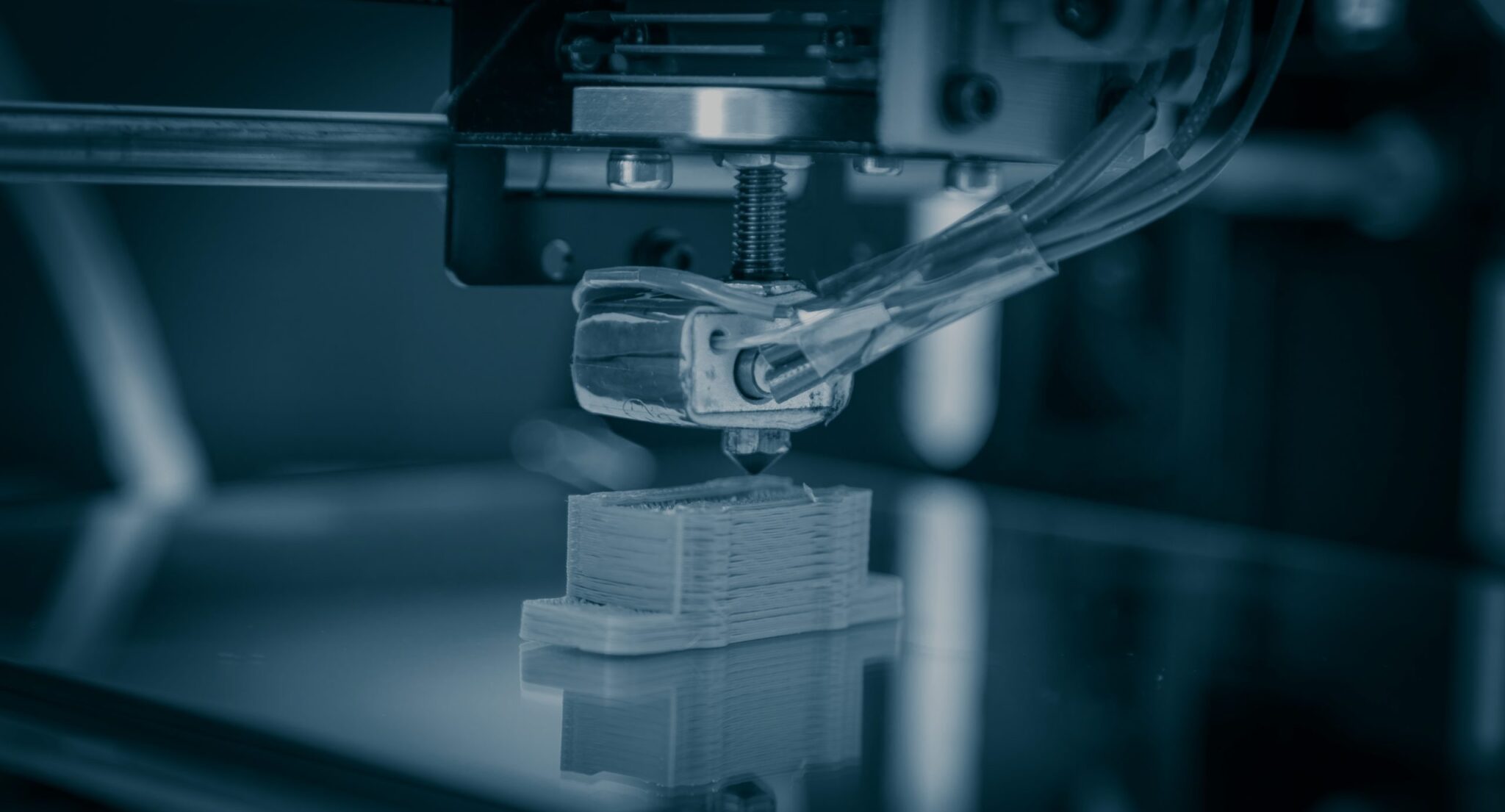

Industrial-grade and desktop FFF share the same core processes, meaning they both use a heated nozzle to melt down thermoplastic material and extrude it one layer at a time until a solid product is formed. What’s more, recent advances in desktop filament extrusion have brought them a little closer to matching the technical capabilities of industrial-grade printing.

Industrial FFF is known for its high accuracy because it has tighter controls due to the processing parameters during printing. Industrial FFF printers use calibration algorithms, heated chambers, dual extrusion, and higher printing temperatures to ensure a high-quality print. Many high-end filament extrusion desktop printers on the market possess these same functions and can even produce parts with a relatively high dimensional accuracy and minimum feature size, approaching the nuance achieved by industrial FFF.

However, hobbyists and engineers alike have been known to conflate desktop printing with industrial-grade printing. Many engineers use small-scale filament extrusion for prototyping purposes. However, prototypes produced via desktop FFF will not achieve the same mechanical properties as those created using industrial-grade technology. Beyond the fundamental technological similarities and capacity for detail, industrial and desktop FFFs differ significantly.

Industrial grade FFF, popular among additive manufacturers, is designed for low to medium production runs, mold printing for low run injection molding, and producing large prototypes quickly. These printers have larger printing areas, so they can either produce one or two large parts or multiple copies of smaller parts during a single print. Industrial-grade printers, like the Stratasys F900, are also known for their repeatability and reliability. The same cannot be said for at-home 3D printers.

Smaller printers also cannot meet the material certifications required for industrial-grade FFF applications. For example, ULTEM® (PEI) is one of the few materials on the market that satisfies fire and smoke toxicity regulations for use in aerospace, and it’s incompatible with desktop printers. Similar results cannot be replicated. The same applies to soluble support materials and the wide variety of engineering plastics used with industrial-grade FFF.

During processing, these materials are often treated with additives to give them certain properties that engineers look for when building products for industrial use-cases, like chemical resistance or greater strength. As such, industrial FFF is an excellent choice for making prototypes, specialized parts, and high-performance consumer-facing products like food and drug packaging.

A desktop printer, better suited for those who want to prototype small volumes of parts or experiment with filament extrusion during their free time, can also be used for low volume production runs of functional parts on a much smaller scale. Thanks to widespread media attention and the growing popularity of 3D printing, desktop printing materials are widely available. Standard PLA is easy to print with and can create finer details that hobbyists may seek in toys or intricate models, while ABS offers greater strength and thermal stability.

Printing with an at-home printer is also much more affordable than printing with industrial FFF. A good office-grade printer costs about $50,000, compared to industrial machines, which often cost hundreds of thousands of dollars fully kitted. However, at-home filament extrusion printers require a high level of user maintenance and near-constant calibration, for which engineers and large manufacturers don’t necessarily have the time. Still, a small-scale filament extrusion printer is a good choice for hobbyists.

Consumers should be careful not to conflate industrial FFF with desktop FFF, or assume they can achieve the same benefits from one machine that they would the other. Industrial FFF will be most beneficial to engineers because of machines’ large build size and the special mechanical properties enabled by industrial-grade FFF. For hobbyists or companies looking to make simple prototypes, a small desktop 3D printer will do just fine for quick, cost-effective builds.

At SyBridge Technologies, we help engineers and designers bring their ideas to life using industrial fused deposition modeling and other dynamic processes. Our dedicated team of engineering experts will see your next project through to the very end, from ideation to manufacturing to fulfillment. Contact us today for a quote.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…