Originally published on fastradius.com on May 3, 2022

Lattice structures are repeating patterns that, when connected, form three dimensional shapes. In an additive manufacturing context, compliant lattice structures open up exciting product design possibilities as designers harness 3D printing technologies to create previously ‘unmakeable’ shapes and parts. When made from elastomers, 3D printed lattice structures are highly deformable and their mechanical properties allow for them to be tuned over a wide range of responses, and used in a spectrum of industries.

However, designing compliant 3D lattice structures requires manufacturing expertise – not to mention the right software tools. At SyBridge, we’ve designed and tested 3D printed lattice structures for a vast range of different products and applications. We’ve used computer simulation to create a large library of data, classifying different lattice structures, and their mechanical properties.

If you’re searching for the right type of 3D lattice structure for your manufacturing project, it’s vital that you understand how different design elements will affect the mechanical responses of your finished part. With that in mind, to help you explore your project’s additive manufacturing potential, we’ve put together a short guide to key 3D lattice design elements – along with four examples of compliant lattice structures selected from our library.

Elastomer 3D lattice structure projects commonly consider some or all of the following four design elements:

This Simple Cubic lattice has a unit cell size of 7.5 mm and a truss width of 2 mm. The modulus is 0.72 MPa.

Buckling response: This structure of the Simple Cubic lattice exhibits buckling instability. After a strain of about 0.05, the modulus is constant at a stress plateau of 25 kPa. Additional deformation does not increase the modulus.

Energy dissipation: The Simple Cubic lattice has an inelastic buckling behavior which produces a different response when it is being loaded and unloaded. The inelastic behavior can be used for many purposes, including energy dissipation.

Applications: The buckling response of this Simple Cubic lattice produces a force threshold that makes it a good candidate for personal protection applications and for shielding sensitive components. This lattice type is also effective for filling gaps between components in assemblies.

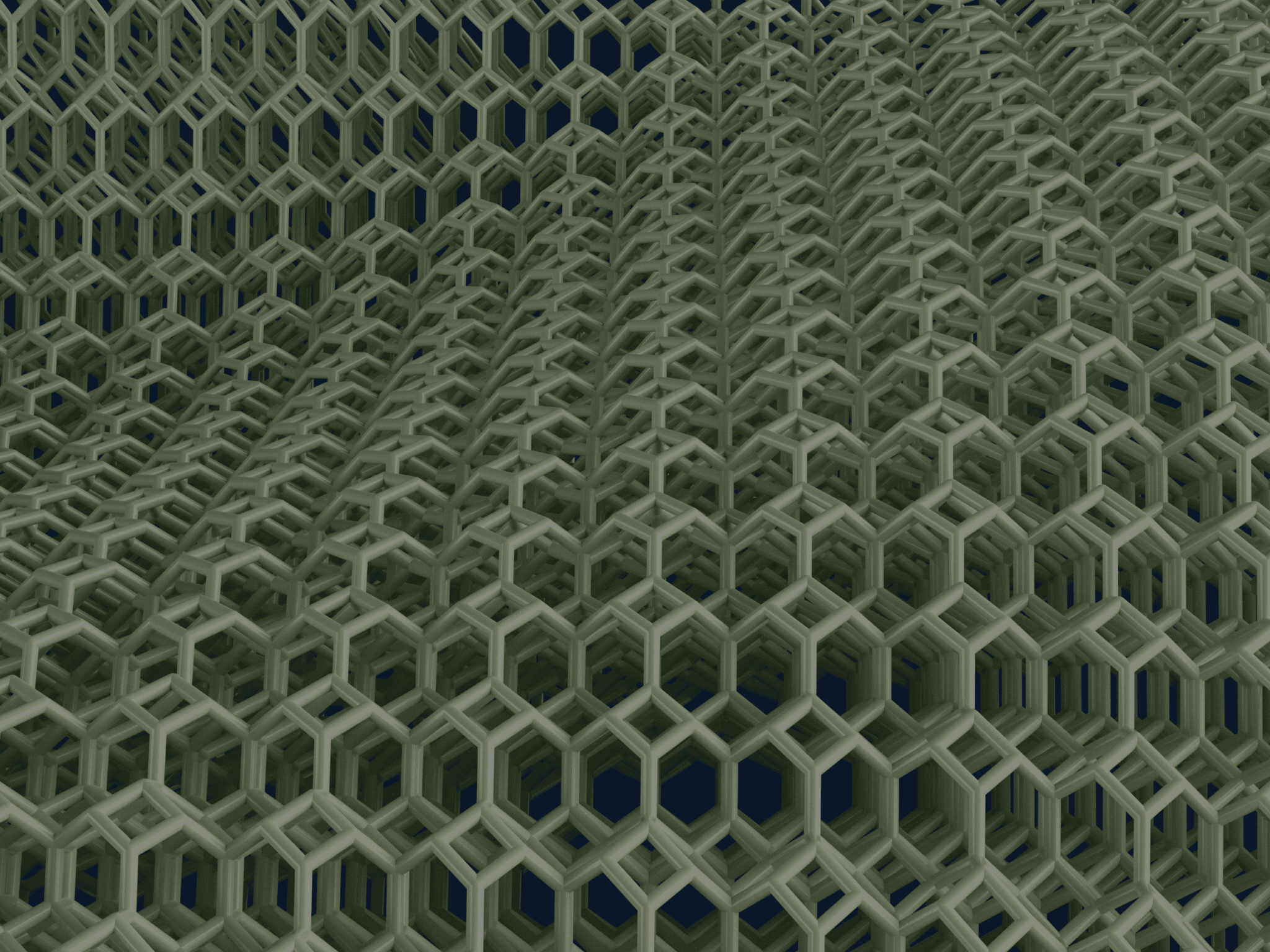

This Kelvin cell lattice has a unit cell size of 10 mm and a truss width of 2 mm. The modulus is 0.44 MPa.

Buckling response: Unlike the Simple Cubic lattice, the Kelvin cell lattice structure has a low buckling point, meaning that its beams stretch in response to force. The Kelvin cell lattice does not have a plateau and compresses continuously with a simple elastic stiffness until it is fully compacted.

Energy dissipation: The Kelvin cell lattice stores energy with its elastic deformation, and it returns to its original shape quickly, like a spring, when force is removed.

Applications: The Kelvin cell lattice is a good candidate for foam replacement in products under static compression such as seat cushions or body pads. With its intricate hexagonal cells, the Kelvin cell lattice is quite visually striking, making it an option for aesthetic and fashion applications.

This Body-Centered lattice has unit cell size of 10 mm and a truss width of 2 mm. The modulus is 0.07 MPa.

Buckling response: The Body-Centered lattice structure has a stretching response, meaning that it responds with increasing force per unit displacement until fully compacted. Its modulus is much lower compared to the Simple Cubic lattice, and it does not have a plateau stress.

Energy dissipation: Like the Kelvin unit, the Body-Centered lattice stores energy with its elastic deformation and returns to its original shape much like a spring when force is removed.

Applications: With its high strain elastic response, the Body-Centered lattice is a good candidate for foam replacement in products under static compression. The angled struts pointing towards the center of the cell make its response even and consistent.

The Body-Centered Cubic (BCC) lattice combines the Body-Centered lattice and Simple Cubic lattice in a single structure. This lattice has a unit cell size 7.5 mm, and a truss width 1 mm. The modulus is 0.23 MPa – which is higher than the Simple Cubic and Body-Centered Cubic lattices listed above.

Buckling response: Since the BCC lattice combines two types of 3D printed lattice, its response is a combination of both. This lattice buckles like the Simple Cubic lattice with a plateau stress (0.12 MPa) but has a more stable post-buckling behavior.

Energy dissipation: Because the BCC lattice combines both an elastic and a buckling response, it is possible to adjust energy storage and dissipation to serve specific applications.

Applications: The BCC lattice is particularly useful for applications that benefit from a tailored elastic and buckling response. It also works well when a product requires energy dissipation with a more stable response than the pure buckling seen in the Simple Cubic lattice.

The four structures highlighted above only scratch the surface of what is possible with an elastomeric 3D lattice structure design. If you’re ready to begin your own 3D printing project, contact us today and make your next project possible.

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

Forget typical cycle times. We're pushing the boundaries of conformal cooling. While traditional approaches deliver…

From left to right: Brayden Janak (apprentice); Logan Vifaquain (CNC machining, Programming and CMM); Ron…

SyBridge Technologies is proud to announce we have been awarded the 2023 General Motors Supplier…

Today, designers and engineers are accustomed to working with digital tools in their day-to-day jobs.…

Optimizing Your Injection Molding Process for Cost-Effective Manufacturing Excellence In today’s competitive landscape, manufacturers are…